Unlocking Energy Efficiency with Kaydeli Heat Recovery Units

In a world where energy conservation and sustainability have become paramount, innovative solutions are constantly emerging to meet the demands of various industries. One such solution is the Kaydeli heat recovery unit – a game-changer that is revolutionizing energy management in manufacturing plants, data centers, power generation facilities, commercial buildings, and hotels. This blog will delve into the working principle behind Kaydeli heat recovery units and explore their diverse applications in different sectors.

Kaydeli heat recovery units are designed to capture waste heat generated during various industrial processes and transfer it to a separate medium such as water or air. This recovered heat can then be repurposed for other applications within the facility, leading to substantial energy savings.

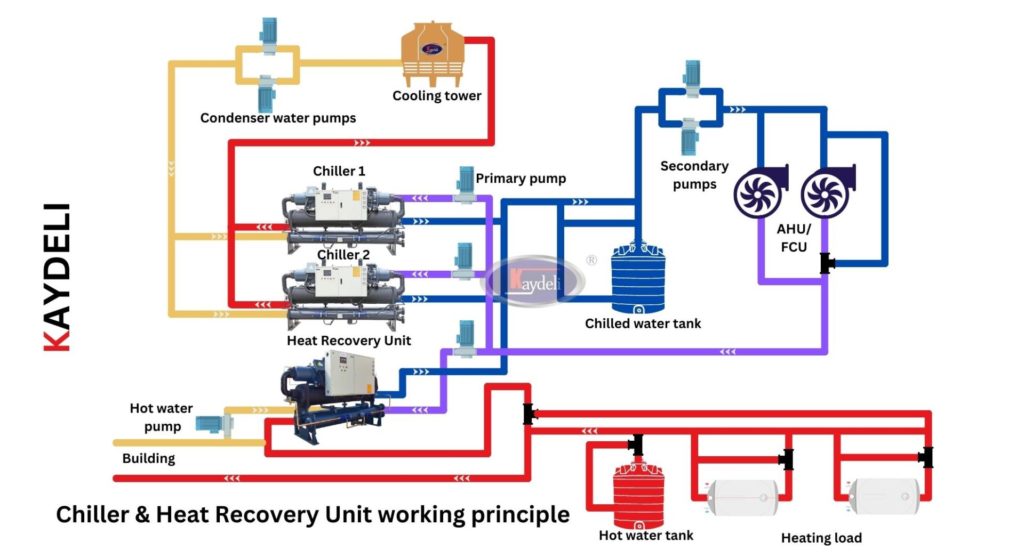

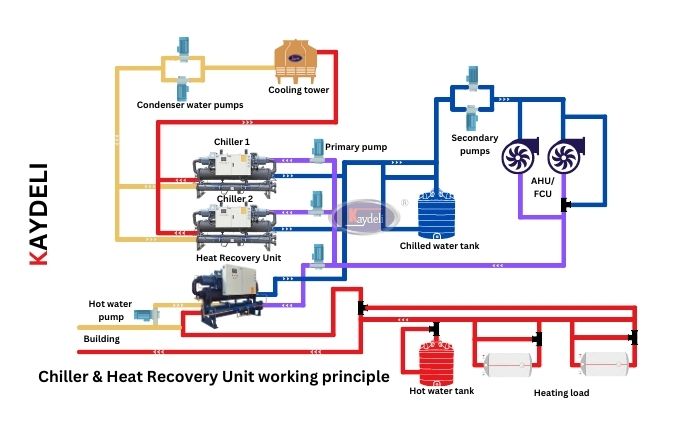

Working principle of heat recovery unit:

An industrial heat recovery unit chiller works on a similar principle, but it utilizes the recovered heat to produce chilled water instead of re-purposing it for other applications. The working principle of an industrial heat recovery unit chiller involves the use of a heat exchanger to transfer the waste heat from the exhaust gases or liquids to a refrigerant.

The refrigerant then undergoes a cycle of compression and expansion to produce chilled water, which can be used for air conditioning or other cooling applications within the facility. This process not only saves energy but also reduces the load on the facility’s cooling system, leading to further energy savings.

The heat reclaim chiller has the capability to generate water temperatures ranging from 48℃ to 65℃ during its operation. Although this temperature range is adequate for many applications, some may require a continuous supply of hot water. Once the building’s cooling load is met, the heat recovery chiller must be turned off to prevent over-cooling of the chilled water loop, which results in a lack of hot water generation.

To address this issue, a system similar to the heating load section in the image should be considered. This system captures heat from the heat recovery chiller when it is available and supplies hot water at the desired temperature for the specific application.

Kaydeli heat recovery units have diverse applications in various industries. Some of the common application fields of Kaydeli heat recovery units are:

Manufacturing Plants: Kaydeli heat recovery units can be used in manufacturing plants to capture waste heat generated during production processes and repurpose it for other applications such as heating water or air conditioning. This can lead to significant energy savings and reduce the plant’s carbon footprint.

Data Centers: Data centers consume a significant amount of energy to power and cool their servers. Kaydeli heat recovery units can be used to capture the waste heat generated by the servers and repurpose it for other applications such as heating water or powering the facility’s cooling system.

Power Generation Facilities: Kaydeli heat recovery units can be used in power generation facilities to capture waste heat generated during the power generation process and repurpose it for other applications such as heating water or air conditioning. This can lead to significant energy savings and reduce the facility’s carbon footprint.

Commercial Buildings: Kaydeli heat recovery units can be used in commercial buildings to capture waste heat generated by HVAC systems and repurpose it for other applications such as heating water or air conditioning. This can lead to significant energy savings and reduce the building’s carbon footprint.

Hotels: Kaydeli heat recovery units can be used in hotels to capture waste heat generated by HVAC systems and repurpose it for other applications such as heating water or air conditioning. This can lead to significant energy savings and reduce the hotel’s carbon footprint, while also providing a comfortable environment for guests.