Fishmeal production industry project

Fish meal feed is a kind of high-protein feed produced by de-oiling, dehydrating, and crushing with fish as raw materials. Because of its high biological value, such as high energy, high calcium, phosphorus, and high protein, it is widely used in livestock and poultry. , Feed for aquatic animals.

The fishmeal industry in my country started late. my country is not only a country with a large demand for fishmeal but also one of the largest producers of fishmeal. During the processing of fishmeal, due to different production techniques, there are many ways to process fishmeal, such as degreasing steam, and low-temperature steam Processing equipment technology also determines the quality and quality of the fish meal.

In the process of fishmeal processing and waste gas treatment, the chiller is used as a process cooling equipment and is also used in the fishmeal production process. It is responsible for cooling the equipment workshop and temperature control of key links.

The following editor of Kaydeli will take you to understand the industry case of fishmeal feed enterprises in the application of water chillers.

Huahai fishmeal in Beihai City, Guangxi is an enterprise that makes fishmeal for feed. Because of the new project, it need to build a refrigeration and cooling room for workshop cooling. After the recommendation of industry friends, I found Kadley to provide a cooling and cooling solution for the workshop.

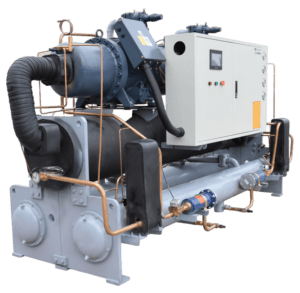

With frequent technical communication between the two parties, the staff of Kaydeli developed the KDS-050SLA water-cooled screw system refrigeration plan. In the plan, the chiller mainly uses Bitzer compressors with a temperature adjustable range of 5 to 35 degrees, a Siemens PLC program controller and other core components constitute.

In addition, a set of 60T water cooling towers, and 5.5kw cooling and ice water circulation pumps are provided, which are used as the water circulation system of the cooling machine room.

It is worth mentioning that for the water-cooled screw main control system, a remote control box is customized for the upper and lower structure of the main machine, and a water tower controller is equipped for the main machine structure.

The on-site chiller is a device that provides cold water, and monitors and controls the working conditions and the temperature and pressure of the outlet water in real-time. PLC is the core of the chiller control unit, which can be realized by collecting on-off signals to judge the operating status of the unit; collecting the output water temperature and pressure signals; outputting on-off signals to control the valve switch and compressor operation of the unit.

Design a remote control system for screw chillers, which can be used for centralized water temperature control. Through tests and actual engineering inspections, the water temperature process parameters are measured accurately and the control is stable. It plays a key role in the safe operation of cooling, water supply quality, energy saving, consumption reduction, etc., The overall scheme has high use value, bringing great convenience and speed to fishmeal production enterprises.

The practice has proved that Kaydeli's non-calibrated water chiller is used in fish meal production enterprises with stable operation and remarkable cooling effects. Kadley chiller can be used not only in fishmeal production and processing, temperature control, but also in waste gas treatment, low-temperature storage, cooling process control in food enterprises, food refrigeration, freezing, and sea (fresh) water aquaculture to cool down process production and equipment Provide stable and reliable refrigeration.