Food processing and manufacturing is a kind of professional technology. In the food field, chillers are often used to control the temperature during food processing to meet the requirements of food production technology, food preservation, and food freezing in a low-temperature environment.

Kaydeli chillers are also widely used in the food processing and manufacturing industry, and Shengsheng Sauce Garden Company is one of the food companies that have cooperated.

Shengsheng Sauce Garden is a technological modern condiment enterprise engaged in the research and development, production and sales of high-end condiments. Its main products include the production of soy sauce, vinegar, sweet noodle sauce, cooking wine and compound condiments. In its soy sauce processing and production line, they use kaydeli brand water chiller.

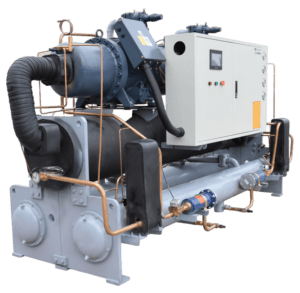

In its production line, water chillers are needed to cool the soy sauce processing equipment. Our Kaydeli engineers have combined the process parameters such as the cooling water temperature, cooling rate, and medium requirements for soy sauce production to develop a set of low-temperature air-cooled screw brine The unit refrigeration scheme, the salt water unit equipment is stable and safe, and has won unanimous praise from Shengsheng Jiangyuan Company! Not only meets the needs of customers but also reduces project investment and operating costs.

In this project, the required chilled water temperature is between -15 and -10 degrees, and the chilled water volume is about 38 cubic meters per hour, which is used to quickly cool the materials to a constant temperature state. KDCS-080SLA low-temperature air-cooled screw brine unit, high-quality anti-corrosion water pump, thermal insulation water tank, valve and other components.

The chilled water adopts a dual-circulation water system design. A high- and low-temperature thermal insulation water tank is designed in the system. The water is pumped from the high-temperature area and returned to the low-temperature water tank after being cooled by the chiller, which district and timely ensure that the food processing production line equipment has sufficient chilled water supply.

The features of Kaydeli low-temperature chiller are:

1. High and low-temperature display and current protection control, equipped with normally open and normally closed output modes for selection;

2. The water circulation system is connected by stainless steel multi-stage pumps and PPR materials, and the water tank of pure stainless steel without coils has strong corrosion resistance;

3. The temperature of chilled water can reach between -5 and -40°C, and the temperature accuracy is ±1°C. In addition, it can be customized and developed upon request;

4. The compressor and other components of the refrigeration system adopt international brands, the refrigeration effect is stable and lasting, and the operation is automatically adjusted according to the load;

5. The “Siemens” PLC microcomputer system is adopted, which can operate without stopping for 24 hours with a high safety factor. To

From 2017 to the present, the operation of this low-temperature air-cooled screw brine unit has been very stable without major failures, and its operating efficiency has increased by about 15% compared with companies in the same industry, which has improved the quality of its products.

The chiller provides a constant low-temperature environment, not only in the food processing field, but also in the food cleaning, food fermentation, food preservation, food packaging, and refrigeration industries. The chiller is also widely used to improve food quality and output. The role of the low-temperature chiller cannot be ignored. Therefore, when choosing a chiller, you must also look for the brand and service of the industry.

Relying on more than 150 professional and technical personnel from Hong Kong’s Kaydeli Research Institute and corporate post-doctoral workstations, Kaydeli independently researches and develops new products with internationally advanced levels of cold and heat, ecology, energy saving, and environmental protection. Products are widely used in food processing and manufacturing, food preservation and freezing, electroplating equipment, embossed plate printing machines, plasma spraying, metallurgy, pharmaceuticals, aquatic product processing, beer, dairy products, commercial air conditioners, medical air conditioners, and other fields to provide customers with tailored Customize the best-integrated refrigeration solution.

Project Date

July 15th 2016

Project Location

China

Project Value

$$$$