The Essential Role of Industrial Chillers in Dairy Process

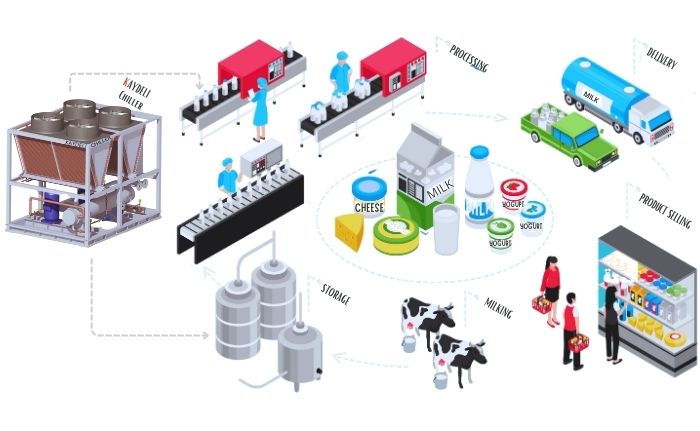

Industrial chillers play a crucial role in the dairy industry, providing essential cooling solutions for various processes. From milk storage and processing to cheese production, industrial chillers are integral to maintaining the quality and safety of dairy products. As the demand for dairy products continues to grow, the reliance on efficient and reliable industrial chillers becomes increasingly significant.

Milk Processing and Storage

In the dairy industry, milk is a primary raw material that undergoes various processing stages before reaching consumers in the form of pasteurized milk, cheese, yogurt, ice cream, and other dairy products. Industrial chillers are essential for maintaining the freshness and quality of milk during processing and storage.

Pasteurization Process

One of the critical steps in milk processing is pasteurization, which involves heating the milk to eliminate harmful bacteria and pathogens. Following pasteurization, rapid cooling is necessary to reduce the milk’s temperature to safe storage levels. Industrial chillers facilitate this rapid cooling process, ensuring that the milk remains safe for consumption while preserving its nutritional value.

Cheese Production

Industrial chillers play a vital role in cheese production, where precise temperature control is essential for curd formation, whey separation, and the aging process. The consistency and quality of cheese greatly depend on maintaining specific temperature conditions throughout these stages. Industrial chillers provide the necessary cooling capacity to support these critical processes, enabling dairy manufacturers to produce high-quality cheeses consistently.

Yogurt and Dairy Desserts

For yogurt and other dairy desserts, maintaining a controlled and low temperature is essential during fermentation and storage. Industrial chillers are instrumental in creating optimal conditions for the fermentation process, which directly impacts the taste, texture, and shelf life of yogurt and dairy desserts. Additionally, industrial chillers contribute to extending the shelf life of these products by ensuring proper storage temperatures are maintained throughout the distribution chain.

Environmental Control

Beyond specific dairy product processing, industrial chillers also contribute to environmental control in dairy facilities. They help regulate temperatures in various areas such as cold storage rooms, production areas, and packaging facilities. This environmental control is crucial for preserving the overall quality of dairy products and ensuring compliance with food safety standards.

Energy Efficiency and Sustainability

With an increasing focus on sustainability and energy efficiency, modern industrial chillers are designed to minimize energy consumption while delivering optimal cooling performance. By investing in energy-efficient industrial chillers, dairy manufacturers can reduce operational costs and minimize their environmental impact. Additionally, some industrial chillers utilize eco-friendly refrigerants, further aligning with sustainable practices in the dairy industry.

Conclusion

In conclusion, industrial chillers are indispensable in the dairy industry, supporting a wide range of processes from milk processing and storage to cheese production and environmental control. Their role in maintaining precise temperatures, ensuring food safety, and enhancing energy efficiency underscores their significance in the production of high-quality dairy products. As the dairy industry continues to evolve, the demand for advanced industrial chillers that offer superior performance and sustainability will remain essential for meeting consumer demands while upholding industry standards. Contact Kaydeli to get a consultation about dairy process chillers.