Temperature Control System for Crystal Growth Furnace

What is a crystal growth furnace system?

A crystal growth furnace system is a machine used to grow crystals in a controlled environment. It typically consists of a furnace, which heats the material to the desired temperature, and a chamber where the crystal growth occurs. The system is designed to maintain specific temperature, pressure, and atmospheric conditions to ensure optimal crystal growth. These systems are widely used in the semiconductor, electronics, and materials science industries.

How does it work?

The working principle of a crystal growth furnace system is based on the controlled heating and cooling of a material to promote crystal growth. As mentioned earlier the system typically consists of a furnace, which heats the material to a high temperature, and a chamber where the crystal growth occurs. The material is melted and then slowly cooled under controlled conditions to promote the formation of a crystal lattice structure. The rate of cooling and other environmental factors such as pressure and gas composition can be adjusted to optimize the crystal growth process. Once the crystal has formed, it can be harvested and used for various applications.

Why a chiller is required for the process?

A chiller is required in a crystal growth furnace system to maintain a stable temperature within the system. The furnace heats the material to a high temperature, but it is important to cool the surrounding environment to prevent unwanted reactions and maintain a stable temperature for crystal growth. A chiller circulates a coolant, typically water, through the system to remove excess heat and maintain a stable temperature. The temperature of the coolant can be adjusted to control the temperature of the system, allowing for precise control of the crystal growth process. Without a chiller, it would be difficult to maintain a stable temperature and optimize crystal growth.

Here is one of our recent projects for an African crystal growth company.

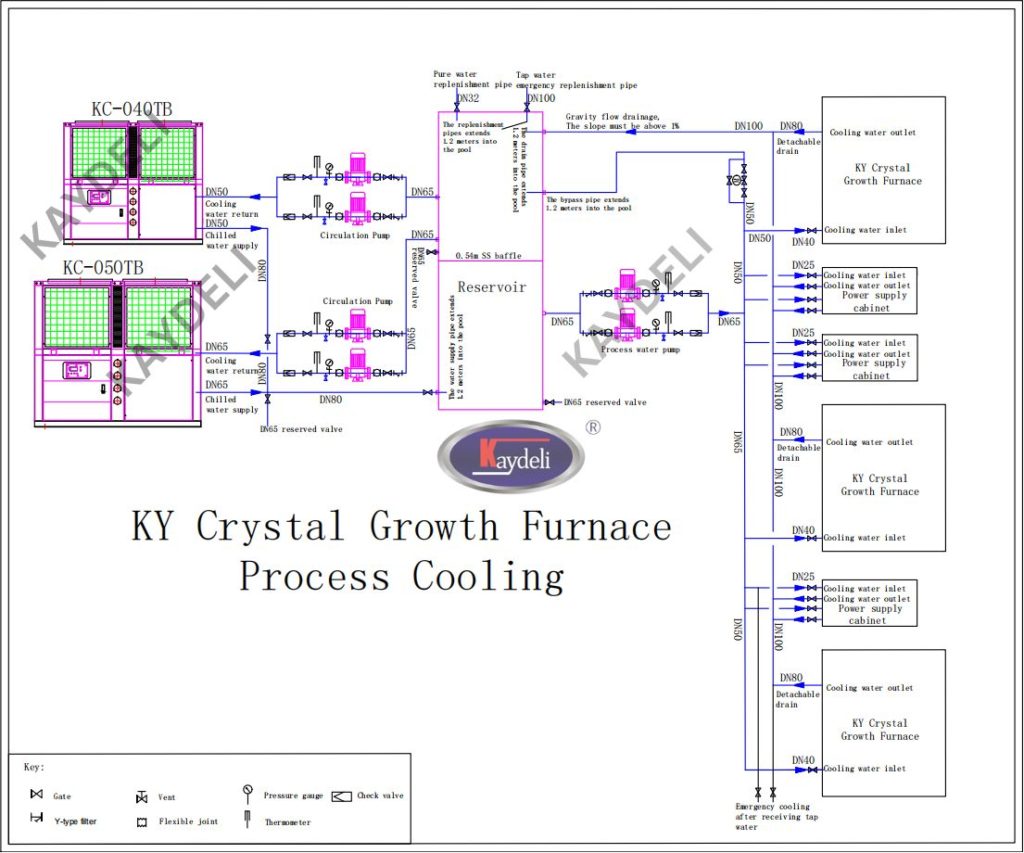

In this project, Kaydeli used two of their air-cooled chillers KC-040TB and KC-050 TB to accomplish the project.

A total of five crystal growth furnaces are installed in this process, three KY crystal growth furnaces, and two GT crystal growth furnaces. The maximum production load operation does not exceed three crystal growth furnaces, and each cycle corresponds to the maintenance of different crystal growth furnaces.

The cooling water demand for a single unit of KY crystal growth furnace equipment is: 6m³/h, the constant temperature of the cooling water supply is 28°C±1°C, and the water inlet pressure of the crystal growth furnace is 0.2MPa-0.22MPa. The gravity flow returns to water, and the water inlet pressure of the power cabinet 0.2MPa-0.3MPa. The outlet water temperature rises by 5~7°C.

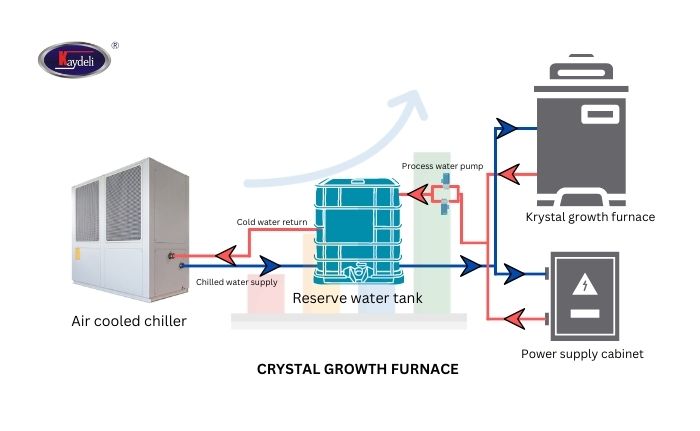

Here is the design of a set of cooling circulating water systems, using two air-cooled industrial chillers to cool down the normal temperature water in the 12 cubic reservoirs to the set temperature, and then the cold water in the reservoir is delivered to the crystal growth furnace equipment by the process water pump.

Two air-cooled industrial chillers are selected, one with a cooling capacity of 113.1KW (the other one has a cooling capacity of 141.4KW), an overall unit composed of four compressors, four independently operating refrigeration systems, process water pumps, air conditioning circulation pumps, and, centrifugal pumps. The material of the water supply and return pipes is 304 stainless steel(SS), and each device is equipped with 304 stainless steel (SS) valves. The air-cooled industrial chiller integrates the refrigeration system, water tank, and water pump for easy use and operation. The unit is compact and occupies a small area. It can be used when it is connected to water and electricity.

Intelligent control, using a high-precision LCD digital controller, can intuitively and accurately measure the outlet water temperature, the operation panel can intuitively display the operation and fault status of the compressor, water pump, and refrigeration system at a glance. Only pressing the start and stop buttons can run the equipment automatically. Simple operation and convenience.

Please feel free to contact Kaydeli for any kind of support in this field as well as for any Industrial chiller requirements.