8 ton injection molding chiller

The Injection molding chiller is designed to handle the high heat loads generated during the injection molding process, ensuring consistent cooling performance and high-quality production. It is also designed to be energy-efficient and low-maintenance, making it a cost-effective solution for injection molding machine operators.

Description

KC-series industrial chiller is mainly applied in the Plastic, printing & Rubber industry; it can accurately control the molding temperature and shorten the molding cycle, increase product quality, and improve production efficiency. They are also widely used in Metal working, Mechanical & Engineering, Chemical & Pharmaceutical, Food & Beverage, Laser, Electronics industry, Textile, Electroplate, Semiconductor testing, Water jet, Vacuum coating, Construction, and Military industries.

Specification

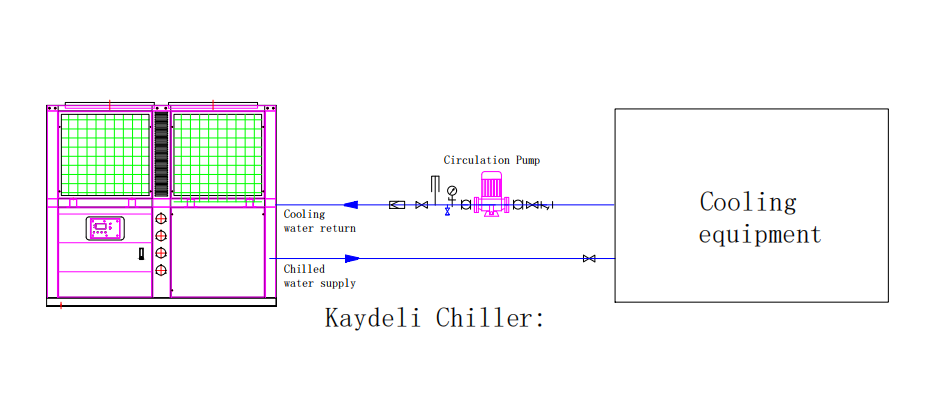

KC-010SA Air Cooled Chiller Operation Structure Diagram

Note: This diagram is only for reference, to get the actual diagram for the specific model please contact the Kaydeli team after placing your order.