15 kw brewery glycol chiller air cooled

Glycol chillers are important in industrial processes that require precise temperature control and stability. They are widely used in food and beverage production, pharmaceutical manufacturing, and HVAC systems. One of the key applications of glycol chillers is in the fermentation process of beer and wine production, where they help to maintain consistent temperatures for optimal yeast growth and fermentation rates.

Description

| Model | KCL-015 | ||

| Cooling capacity | kW | 11.80 | |

| kcal/h | 10148 | ||

| Power consumption | kW | 14.8 | |

| Power | 3PH-(200V,220V, 415V,380V)-50HZ/60Hz | ||

| Refrigerant | Type | R404a | |

| Control method | Externally balanced expansion valve | ||

| Compressor | Type | Fully enclosed scroll (Piston) | |

| Power | kw | 13.20 | |

| Condenser | Type | High-efficient copper tube aluminum fin | |

| Evaporator | Type | Shell and Tube | |

| Chilled fluid flow | m3/h | 5.03 | |

| Pipe | B | PT 2″ | |

| Water pump | Power | kw | 1.1 |

| Protective devices | Compressor overheating, over current, high and low pressure, over temperature, flow switch, phase sequence, phase-missing, exhaust overheating, and anti-freezing protection. | ||

| Dimensions | L | mm | 1600 |

| W | mm | 900 | |

| H | mm | 1640 | |

| Weight | kg | 550 | |

Note:

- The cooling capacity is based on: Chilled water inlet/outlet water temperature (Evaporator)-5℃/-10℃ or -20℃/-25℃. Cooling water inlet/outlet (Condenser) 30℃/38℃.

- Working range: The temperature range of the frozen aqueous solution is -25℃ to -5℃, and the temperature difference between the inlet and outlet of the frozen aqueous solution is 3℃ to 8℃.

- Workable ambient temperature 5℃ to 35℃.

Kaydeli reserved the right to change the above parameters or dimensions without prior notice.

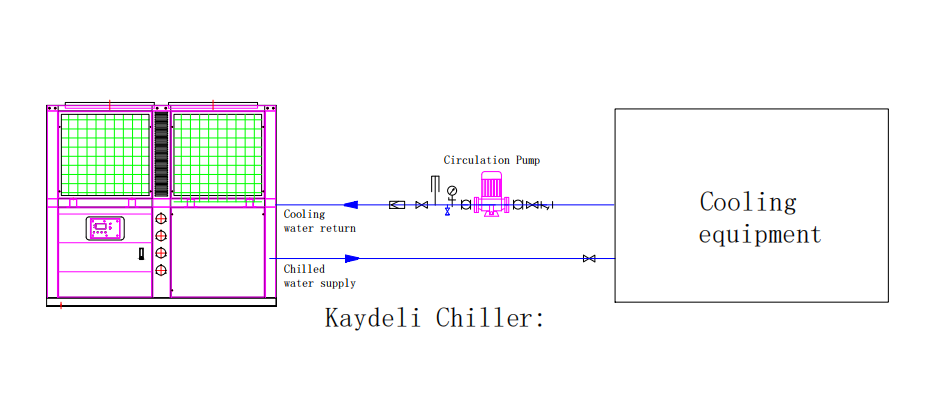

Installation diagram

Note: This is only a reference diagram of the installation process, please ask the Kaydeli team for the actual drawing.