100 ton water cooled screw chiller

The product keeps up with the development trend of the times, adhering to the design concept of “high efficiency, reliability, energy saving, and environmental protection” to provide users with excellent refrigeration equipment. Widely used in hospitals, hotels, business buildings, manufacturing industries, anodizing, refrigeration, reactor plant, chemical industry, laboratory, etc.

Description

Well Known Brand Compressor

- The unit adopts Germany BITZER or Taiwan HANBELL brand semi-hermetic screw compressor. The latest 5 to 6 patented screw rotor profile with excellent efficiency.

- Adjustable infinite or closely stepped capacity control features energy-efficient, stable, and quiet running.

- Most advanced patented highest precision manufacturing process.

- Built-in full intelligent monitoring and protection including thermal motor temperature monitoring, phase sequence monitoring, manual reset lock-out, and oil temperature sensor.

- Wide range of refrigerants for option, including R134a, R407c, and R22(R404a, R507c upon request).

Micro–programming Control System

- Industrial PLC centralized control combined with compressor capacity control system, precisely monitor.

- Integrated protection for low temperature, high/low pressure, anti-freezing, phase missing, anti-phase, overload, motor over temperature, oil differential, flow switch, and start-up latency.

- Optional operation language, menu leading, and unit running state are easy to adjust.

Easy Installation, Reliable Running

- Closely stepped start-up, minimizing the impact on electricity.

- Steady and safe running, low vibration, easy for installation.

- Compact structure, less space demand, and light in weight, easy for transport and installation.

- Completely wired, inspected, and tested pre-delivery, saving installation time and cost.

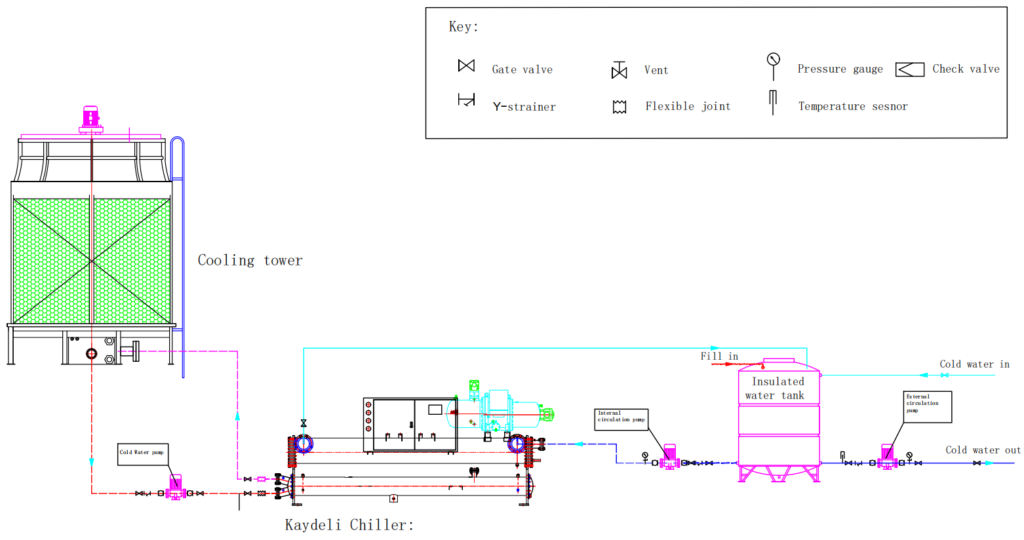

Water Cooled Water Chiller operation diagram

Note: This diagram is only for reference, to get the actual diagram for the specific model please contact the Kaydeli team after placing your order.