Enhance Your Bottle Blowing Process with Kaydeli Chiller

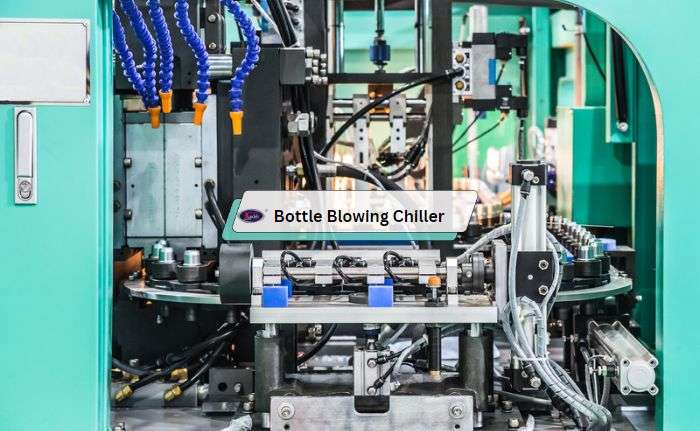

Bottle blowing is a manufacturing process used in the production of plastic bottles, where preforms or molds of plastic are heated and blown into the desired shape of the final product. The success of the bottle-blowing process depends on several factors, one of which is temperature control. To ensure consistent quality and efficiency in the bottle-blowing process, it is essential to have a reliable cooling system that can regulate the temperature of the plastic preforms.

Kaydeli is a leading manufacturer of industrial chillers, including those used in the bottle-blowing process. In this article, we will explore the features and benefits of Kaydeli bottle-blowing chillers.

Features of Kaydeli Bottle Blowing Chillers Kaydeli Bottle Blowing Chillers are designed to provide precise temperature control, reliability, and energy efficiency to the bottle-blowing process. Some of the key features of Kaydeli chillers include:

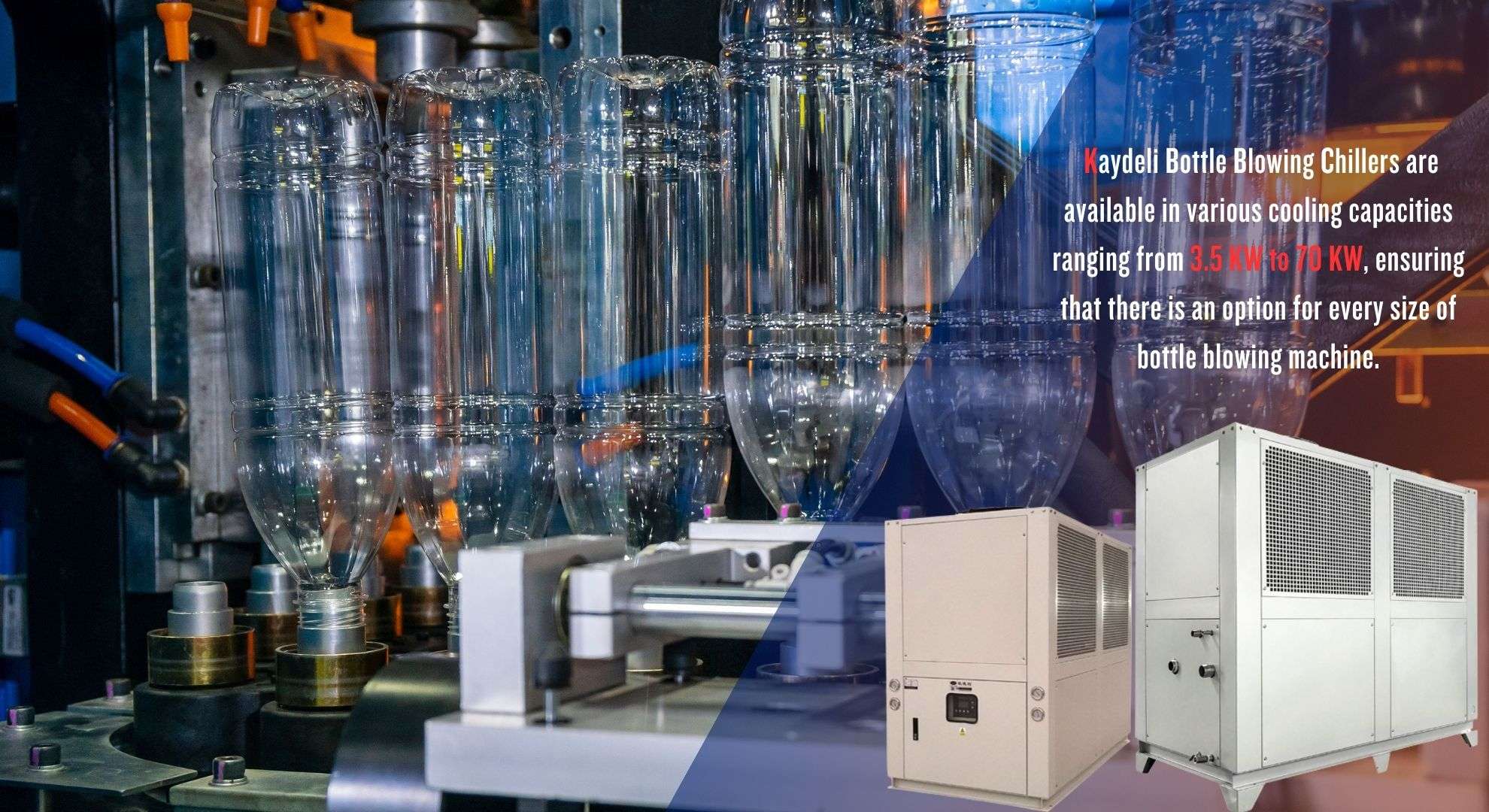

High Cooling Capacity: Kaydeli Bottle Blowing Chillers are available in various cooling capacities ranging from 3.5 KW to 70 KW, ensuring that there is an option for every size of the bottle-blowing machine.

Energy Efficiency: Kaydeli Bottle Blowing Chillers are equipped with world-famous efficient compressors like Danfoss, and Panasonic that help to reduce energy consumption and operating costs.

High-Quality Components: Kaydeli Bottle Blowing Chillers are built with high-quality components, such as compressors, evaporators, and condensers, that are designed for durability and reliability.

Precise Temperature Control: Kaydeli Bottle Blowing Chillers are equipped with microprocessor-based controllers that provide precise temperature control within +/- 0.5°C~1°C, ensuring consistent product quality.

User-Friendly Design: Kaydeli Bottle Blowing Chillers are designed with ease of use in mind, with features such as LCD displays, fault alarms, and remote control options for convenient operation and monitoring.

Benefits of Kaydeli Bottle Blowing Chillers The use of Kaydeli Bottle Blowing Chillers in the bottle-blowing process provides several benefits, including:

Improved Product Quality: The precise temperature control provided by Kaydeli Bottle Blowing Chillers ensures consistent product quality, resulting in better-looking, higher-quality bottles.

Increased Efficiency: Kaydeli Bottle Blowing Chillers can help to increase efficiency in the bottle-blowing process by reducing the cooling time required and increasing the number of bottles that can be produced in a given amount of time.

Cost Savings: Kaydeli Bottle Blowing Chillers are designed to be energy efficient, which can lead to cost savings in operating expenses over time.

Increased Equipment Lifespan: The use of Kaydeli Bottle Blowing Chillers can help to extend the lifespan of bottle-blowing machines by reducing the amount of wear and tear on the equipment.

Easy Maintenance: Kaydeli Bottle Blowing Chillers are designed for easy maintenance, with features such as removable filters and easy access to components for quick repairs.

Conclusion: Kaydeli Bottle Blowing Chillers are an excellent choice for any manufacturer looking to improve the quality and efficiency of their bottle-blowing process. With their high cooling capacity, energy efficiency, and precise temperature control, Kaydeli chillers can help to increase productivity, reduce operating costs, and improve the overall quality of the final product. Additionally, their user-friendly design and easy maintenance make them a convenient and reliable option for any bottle-blowing operation. If you are looking for any kinds of chillers for your project please, don’t hesitate to contact us.

Keep Your Pool and Spa Cool with Kaydeli Chillers

Swimming pools and spas are a great way to relax and enjoy the outdoors, especially during the warmer months of the year. However, as the temperature rises, so does the temperature of the water, making it less comfortable to swim or soak in. This is where the swimming pool and spa chillers come in.

A swimming pool and spa chiller is a type of chiller that is designed to cool the water in your pool and spa to a comfortable temperature. These chillers work by circulating the water through a heat exchanger, which is cooled by either air or water. The cooled water is then returned to the pool and spa, lowering the temperature of the water.

There are different types of swimming pool and spa chillers available, including air-cooled chillers, water-cooled chillers, and dual-temperature chillers.

Here are some more details about the types of chillers and which one may be best for your needs:

Air-cooled chillers:

Air-cooled chillers are the most common type of chiller for swimming pools and spas. They work by using a fan to blow air across a heat exchanger, which cools the water. These chillers are more affordable and easier to install than water-cooled chillers, but they are also less efficient and may not be suitable for larger pools or spas.

Water-cooled chillers:

Water-cooled chillers use a water source, such as a nearby lake or pond, to cool the water. These chillers are more efficient than air-cooled chillers, making them ideal for larger pools or spas. However, they are also more expensive to install and require access to a water source like a water tower.

Dual-temperature chillers:

Dual-temperature chillers are designed to cool the pool and spa simultaneously. They are ideal for those who have both and want to maintain different water temperatures for each. These chillers are a bit more expensive than single-temperature chillers as they require a heating device and some more equipment, but they offer the convenience of cooling both the pool and spa at the same time.

Low-temperature chillers:

Low-temperature chillers are designed to cool water to temperatures below 60°F (15.5°C) and are ideal for those who have ice rinks or other applications that require very cold water. These chillers are more expensive and require special considerations, such as a glycol solution to prevent freezing.

When choosing a chiller, it’s essential to consider the size of your pool or spa, your budget, and your specific needs. An air-cooled chiller may be the best choice if you have a small residential pool or spa. If you have a larger commercial pool or spa, a water-cooled chiller may be more efficient. If you have both a pool and spa and want to cool both, a dual-temperature chiller may be the best option.

Kaydeli is an industrial chiller manufacturing company that specializes in producing high-quality chillers for various applications, including swimming pools and spas. They offer a wide range of chillers, including air-cooled, water-cooled, and dual-temperature chillers, to suit your specific needs.

Kaydeli’s chillers are made from high-quality materials and are designed to be energy-efficient, durable, and easy to maintain. They offer a variety of features, such as digital temperature control, automatic shut-off, and quiet operation, to make using their chillers convenient and hassle-free.

Whether you have a small residential pool or a large commercial spa, Kaydeli can help you find the right chiller for your needs. Our team of experts can help you choose the right chiller based on the size of your pool or spa, your budget, and your specific requirements.

In conclusion, swimming pool and spa chillers are an essential investment for anyone who wants to enjoy their pool or spa throughout the year, regardless of the temperature.

Kaydeli is an industrial chiller manufacturing company that offers a wide range of chillers, including air-cooled, water-cooled, and dual-temperature chillers, to help you keep your pool and spa at a comfortable temperature.

Contact Kaydeli today to find the right chiller for your needs.

Why water cooled chillers are important?

Water-cooled chillers play a critical role in the cooling industry, providing precise and efficient cooling for a wide range of industrial applications. These systems use water as a coolant to remove heat from processes and equipment, making them an ideal choice for large-scale cooling needs.

One of the key benefits of water-cooled chillers is their energy efficiency. Compared to air-cooled chillers, water-cooled systems use water as a more efficient heat transfer medium, resulting in lower energy consumption and reduced operating costs.

This makes them a cost-effective solution for cooling large industrial processes, such as data centers, manufacturing plants, and hospitals.

Another benefit of water-cooled chillers is their quiet operation. Unlike air-cooled chillers, which require large fans to circulate air, water-cooled systems operate quietly, making them ideal for use in noise-sensitive environments, such as hospitals, schools, and residential areas.

Water-cooled chillers also have a longer lifespan than air-cooled chillers. Because they are not exposed to harsh outdoor conditions, such as extreme temperatures, rain, and snow, they are less prone to wear and tear.

Hence, they are easier to maintain and repair, as their components are located indoors and are not subject to weather-related damage.

Water-cooled chillers are also highly customizable, making them a versatile choice for many different cooling needs. They can be designed to handle a wide range of cooling loads and can be customized to meet specific requirements, such as temperature control and humidity control.

For industrial settings, precise temperature control is critical for ensuring optimal product quality and equipment performance. Water-cooled chillers provide greater thermal stability and consistency than air-cooled systems, allowing for improved process control and reduced downtime.

Water-cooled chillers are widely used in a variety of industries, from food and beverage production to pharmaceutical manufacturing to HVAC systems. In the food and beverage industry, water-cooled chillers are used to maintain precise temperatures during the fermentation process of beer and wine production, as well as in other food processing applications.

As for the pharmaceutical industry, water-cooled chillers are used to regulate the temperature of sensitive equipment and samples, ensuring accuracy and reliability in research and testing.

In HVAC systems, water-cooled chillers are used to cool buildings, providing efficient and consistent temperature control.

One of the primary advantages of water-cooled chillers is their ability to handle large cooling loads. They are capable of providing cooling to multiple processes and equipment simultaneously, making them a versatile and reliable choice for industrial applications.

Additionally, water-cooled chillers can be designed to operate with a variety of different refrigerants, allowing them to meet the specific needs of different applications.

Water-cooled chillers are also a more sustainable choice compared to air-cooled chillers. Because they use water as a coolant, they have a smaller environmental footprint and produce fewer greenhouse gas emissions.

In conclusion, water-cooled chillers are an important component of the cooling industry, providing efficient and reliable cooling for large-scale industrial processes and equipment. Their energy efficiency, quiet operation, longer lifespan, and customizable design make them a versatile and cost-effective solution for a wide range of cooling needs.

Contact Us: If you have any questions or would like to learn more about water-cooled chillers, feel free to contact us. Our team of experts is ready to provide you with the information you need to make the best cooling decisions for your industrial application.

Keeping Your Crypto Cool

Bitcoin and cryptocurrency mining requires a significant amount of computing power, which in turn generates a substantial amount of heat. This heat needs to be dissipated to prevent damage to the mining hardware and to maintain optimal operating conditions.

To achieve this, many mining operations rely on cooling systems, such as air conditioners, water-cooled chillers, and dry chillers.

Kaydeli’s dry chiller technology is an excellent choice for cooling bitcoin and cryptocurrency mining operations. Unlike water-cooled chillers, which require a water supply and complicated piping systems, dry chillers use air to dissipate heat, making them easier to install and maintain.

Dry chillers also offer superior energy efficiency and cost savings, as they require less energy to operate compared to traditional cooling methods.

Kaydeli’s dry chiller technology is designed to meet the high-capacity cooling requirements of bitcoin and cryptocurrency mining operations.

These chillers can provide up to 1200 kW of cooling capacity, ensuring that even the most demanding mining operations stay cool and efficient.

They are also designed with advanced controls and monitoring systems, allowing for precise temperature and humidity control, ensuring optimal operating conditions for mining hardware.

In addition to their energy efficiency and high-capacity cooling, Kaydeli’s dry chillers are also reliable and durable, built to withstand the harsh operating conditions of mining facilities.

With minimal maintenance requirements, these chillers provide long-lasting, trouble-free operation, reducing downtime and maximizing productivity.

Overall, the use of Kaydeli’s dry chiller technology can greatly benefit bitcoin and cryptocurrency mining operations, providing reliable, energy-efficient, and high-capacity cooling solutions. With the increasing demand for bitcoin and other cryptocurrencies, it is essential to have a robust and efficient cooling system in place to maintain optimal operating conditions and ensure the longevity of mining hardware.

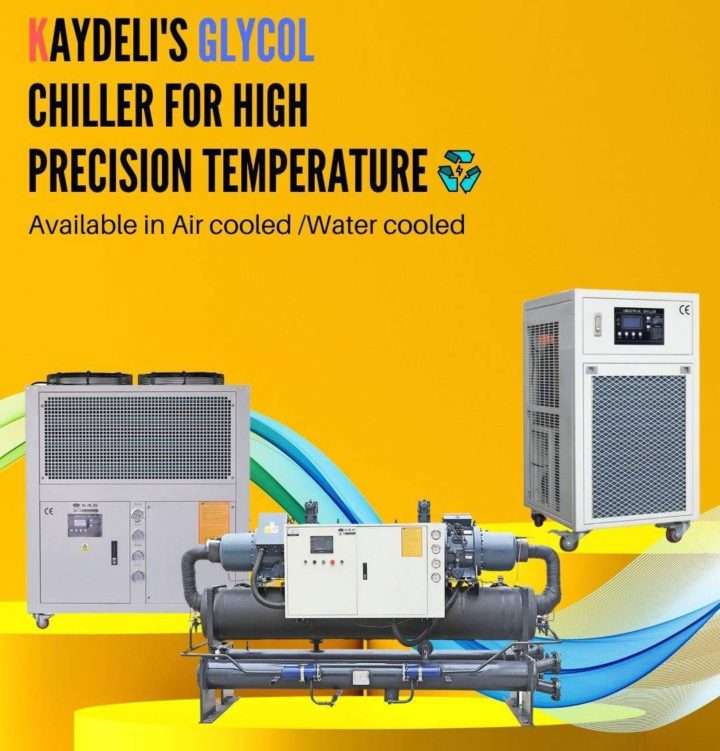

Why Glycol Chillers Are For High Precision Cooling

Glycol chillers are used in various projects across different industries for their ability to maintain precise temperature control. They work by circulating a mixture of water and glycol through a closed-loop system.

The chilled mixture is then used to cool down the process equipment, which helps maintain a stable temperature and prevent overheating.

For example, in the food and beverage industry, glycol chillers are commonly used to maintain the temperature of fermenters, which are used to make beer, wine, and other alcoholic beverages. They are also used in dairy production to keep milk and cheese at the right temperature.

In the pharmaceutical industry, glycol chillers are used in the manufacturing of drugs and vaccines.

They are used to keep the temperature stable during the production process, which is crucial for ensuring the quality and efficacy of the final product.

In the plastics industry, glycol chillers are used to cool down molds used for injection molding, extrusion, and blow molding processes. These processes can generate a lot of heat, and the use of glycol ensures that the molds remain at the correct temperature, which helps maintain product quality and prevent damage to the equipment.

In the HVAC industry, glycol chillers are used to cool down the water used in air conditioning systems. This helps regulate the temperature and humidity of indoor spaces, ensuring comfort for occupants.

Overall, glycol chillers are a versatile solution for maintaining precise temperature control in various projects and industries. They offer reliability, efficiency, and ease of use, making them a popular choice for businesses that require temperature-sensitive processes.

Kaydeli is a leading manufacturer of high-quality Glycol chillers, which are widely used in various industries, including food and beverage, chemical, and pharmaceuticals.

These chillers are known for their high efficiency, reliability, and ease of use, making them a popular choice for businesses that require precise temperature control for their processes.

Glycol chillers work by circulating a mixture of water and glycol through a closed-loop system. The chilled mixture is then used to cool down the process equipment, which helps maintain a stable temperature and prevent overheating. The use of glycol also prevents freezing, making it a versatile coolant for a wide range of applications.

One of the key features of Kaydeli’s Glycol chillers is their high efficiency. These chillers use advanced compressors and heat exchangers to deliver maximum cooling performance while minimizing energy consumption.

This not only saves businesses money on their energy bills but also reduces their carbon footprint, making them a sustainable choice for environmentally conscious organizations.

Another advantage of Kaydeli’s Glycol chillers is their reliability. These chillers are built to last, with high-quality components and robust construction that can withstand even the most demanding environments. They are also designed for easy maintenance, with accessible components and user-friendly controls that make it simple to diagnose and fix any issues.

Kaydeli’s Glycol chillers are also highly customizable, with a wide range of options to suit different needs and applications. They are available in a variety of sizes and capacities, with multiple compressor configurations and control options to choose from. This allows businesses to select a chiller that is perfectly tailored to their requirements, whether they need to cool a small laboratory setup or a large-scale industrial process.

In conclusion, Kaydeli’s Glycol chillers are a reliable, efficient, and versatile solution for businesses that require precise temperature control for their processes. With their high-quality construction, user-friendly controls, and wide range of customization options, they are an excellent investment for organizations that value quality and efficiency.

If you have any questions regarding Kaydeli chillers please, feel free to contact us.

Green Refrigerants in Chillers to Reduce Emissions

Introduction: What is Green Refrigerant and Why is it Important in Industrial Chillers?

Green refrigerants are becoming increasingly important in industrial chillers as they help reduce the impact of climate change. Refrigerants are used in HVAC systems to keep a building cool and are known to be the largest contributor to greenhouse gas emissions. Green refrigerants, like hydrofluoroolefins (HFOs) and hydrochlorofluorocarbons (HCFCs), have a much lower global warming potential than traditional refrigerants, making them a much more sustainable solution for cooling. Industrial chillers that use green refrigerants can not only help reduce carbon emissions but also reduce energy costs.

How Green Refrigerants Can Help Decrease Emissions from Industrial Chillers

Industrial chillers are a major source of greenhouse gas emissions, contributing to global warming and ozone depletion. The use of green refrigerants, such as natural refrigerants or hydrocarbon refrigerants, can help reduce these emissions and protect the environment. Natural refrigerants have a much lower ozone depletion potential (ODP) and global warming potential (GWP) than traditional synthetic refrigerants. They are also more efficient, leading to lower energy consumption and cost savings for businesses. By switching to green refrigerants, businesses can reduce their environmental impact while still providing reliable cooling solutions for their customers.

The Benefits of Using Green Refrigerants in Industrial Cooling & Heating Systems

With the world’s growing demand for energy, green refrigerants are becoming increasingly important in industrial cooling and heating systems. Green refrigerants are non-toxic, non-ozone-depleting chemicals that can replace traditional hydrofluorocarbons (HFCs) in industrial cooling and heating systems. Green refrigerants offer numerous benefits such as improved energy efficiency, lower carbon emissions, and improved safety.

What Are the Challenges Involved With Implementing Green Refrigerants in Industrial Chillers?

With the ever-increasing environmental concerns, businesses are looking for ways to reduce their carbon footprint by implementing green refrigerants in their industrial chillers. This switch to natural refrigerants has a lot of benefits, however, some challenges need to be taken into consideration before making the switch. These challenges include assessing the environmental impacts of using green refrigerants and ensuring that all safety considerations are met when using natural refrigerants.

How to Transition Towards a Sustainable Choice

With the world’s resources rapidly depleting and global warming becoming a more pressing issue, we must make a conscious effort to transition toward sustainable choices. We must take steps to reduce our carbon footprint and ensure that our actions do not harm the environment. Making the switch to sustainable options is not only good for the planet but also beneficial for businesses as it can help them save money in the long run. Kaydeli is one of the industrial chiller manufacturers that offer and suggest to use of environment-friendly refrigerants. Let’s all work together to make the world a better place.

Some lists of eco-friendly refrigerant

R-134,R-152,R290,R600,R404,R-407,R-410,R-413,R170,R717, etc.

The Benefits of Utility for Chillers

Introduction: What is a Utility for Industrial Chillers & Its Benefits

Industrial chillers are an essential part of many industrial processes, ensuring that temperatures remain constant and regulated. A chiller utility is a type of system that helps to improve the efficiency of a chiller system by providing data on the performance and maintenance needs of the chillers. It can help to identify any potential issues, allowing for quick and easy repairs to be made. Not only does this improve the efficiency of the system, but it also reduces energy costs associated with running chillers. Additionally, a chiller utility can provide valuable insights into how well each individual component is performing and how they can be optimized for better performance.

How to Optimize Your Industrial Chiller with a Utility

Industrial chillers are used in a variety of industries to cool and maintain temperatures for a variety of processes. Optimizing the performance of these chillers is essential to maximize efficiency, improve cooling capacity, and reduce energy costs. By using a utility-based optimization system, you can ensure that your industrial chiller is running at its peak performance. This article will explain how you can optimize your industrial chiller with a utility-based optimization system in order to maximize efficiency and reduce energy costs.

What Are the Different Types of Utilities Available for Industrial Chillers?

Industrial chillers are used in a variety of industries to maintain the temperature of materials and processes. To ensure their optimal performance, it is important to use the right utilities for industrial chillers. There are various types of utilities available for industrial chillers, ranging from cooling systems to energy-saving options. These utilities can help improve the efficiency and reliability of your chiller system, while also reducing operational costs.

In this article, we will discuss the different types of utilities available for industrial chillers and how they can help improve your cooling system’s performance. The most common type of utility used for industrial chillers is a cooling system. These systems are designed to cool the air that enters the machine and pump it into a separate area where it can be cooled further. This can provide an affordable alternative to regular refrigeration. Other types of utilities available for industrial chillers include energy-saving options, such as hot water heat exchangers, cooling tower bypasses, and economizer bypasses.

Using Data Analytics and Automation to Monitor and Control Your Industrial Chiller’s Performance

Data analytics and automation are becoming essential tools for industrial chillers to monitor and control their performance. With the help of analytics tools, industrial chillers can track their performance in real-time, identify any potential issues before they become a problem, and get insights on how to optimize their operations. Automation solutions provide an efficient way to manage chillers by automating tasks such as scheduling maintenance, controlling temperature settings, and monitoring energy consumption. By using these data-driven tools, industrial chillers can ensure that they are running at peak efficiency while reducing their energy costs.

How to Choose the Best Utility For Your Industrial Chiller?

Choosing the right utility for your industrial chiller can be a daunting task. It is important to understand what type of utility will best suit your specific application and requirements. There are several factors to consider when selecting the best utility for your industrial chiller, including cost, efficiency, and reliability. With careful consideration of these factors, you can ensure that you are getting the most out of your investment. In this article, we will discuss some tips on how to choose the best utility for your industrial chiller.

The cost of your utility can have a significant impact on the total cost of your industrial chiller. Generally speaking, you should select a utility that is less expensive than the chiller. This will help to keep your energy costs as low as possible and also provide a lower total cost of ownership (TCO) for your investment. Additionally, always remember to perform an annual capital cost comparison between the various utilities in order to ensure that you are getting the best deal on utility costs for your industrial chiller.

Efficiency is often overlooked when selecting the best utility for an industrial chiller. You might be thinking about a chiller with the most BTUs and not consider the energy required to operate it. Depending on the usage of a certain unit, fuel cost may not be that important. For example, if you are using an air compressor for drying and cooling then fuel cost may not be an issue as each unit is used only once or twice per day. On the other hand, if you are using an industrial chiller to cool water continuously over extended periods of time then fuel cost should factor into your decision-making process when selecting a utility unit.

To get an optimized and cost-friendly industrial chiller please contact us.