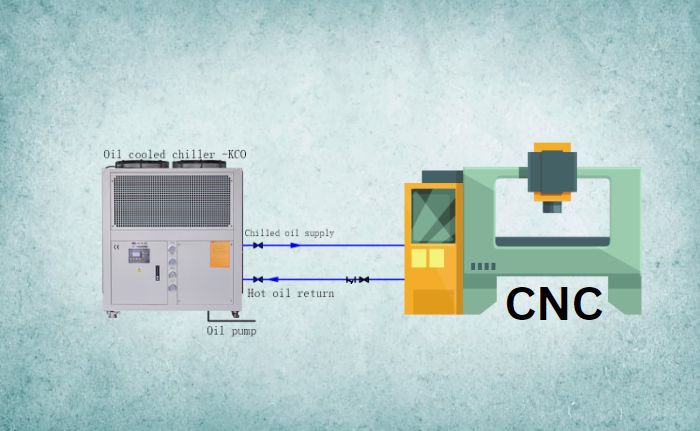

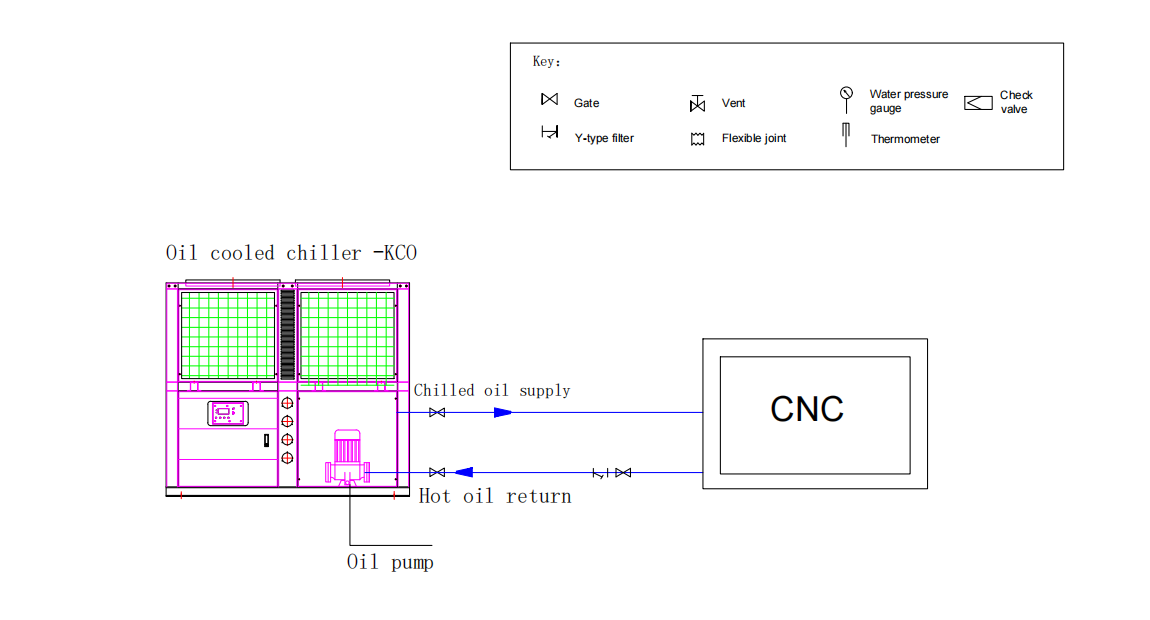

Why Oil cooled chillers are important for CNC machines

CNC and hydraulic machines are essential tools in many industrial settings, and they require a reliable cooling system to maintain optimal performance. This is where oil-cooled chillers come in. In this article, we’ll explore the importance of oil-cooled chillers and the different types of chillers used for CNC and hydraulic machines.

Oil-cooled chillers are designed to cool down the oil that is used to lubricate and cool down the machines. This is important because the oil can become too hot, which can lead to damage to the machines and a decrease in performance. By using an oil-cooled chiller, the oil can be kept at a consistent temperature, which helps to prolong the life of the machines and maintain their performance.

There are several types of oil-cooled chillers that are commonly used for CNC and hydraulic machines. These include:

Air-cooled oil chillers: These chillers use air to cool down the oil. They are typically less expensive than water-cooled chillers, but they are also less efficient.

Water-cooled oil chillers: These chillers use water to cool down the oil. They are more efficient than air-cooled chillers, but they are also more expensive.

Portable oil chillers: These chillers are designed to be portable, so they can be moved around as needed. They are typically smaller than other types of chillers, but they are still effective at cooling down the oil.

At Kaydeli, we offer a range of oil-cooled chillers that are specifically designed for CNC and hydraulic machines. Our chillers are known for their reliability, efficiency, and eco-friendliness. For example, our oil-cooled chiller units (from 1 ton to 30 tons) are designed to provide consistent cooling for CNC and hydraulic machines, ensuring optimal performance and longevity.

In conclusion, oil-cooled chillers are an essential component of any industrial setting that uses CNC and hydraulic machines. By maintaining a consistent temperature for the oil, these chillers help to prolong the life of the machines and maintain their performance. At Kaydeli, we offer a range of oil-cooled chillers that are specifically designed for CNC and hydraulic machines, ensuring that our customers have access to the best possible cooling solutions for their needs.

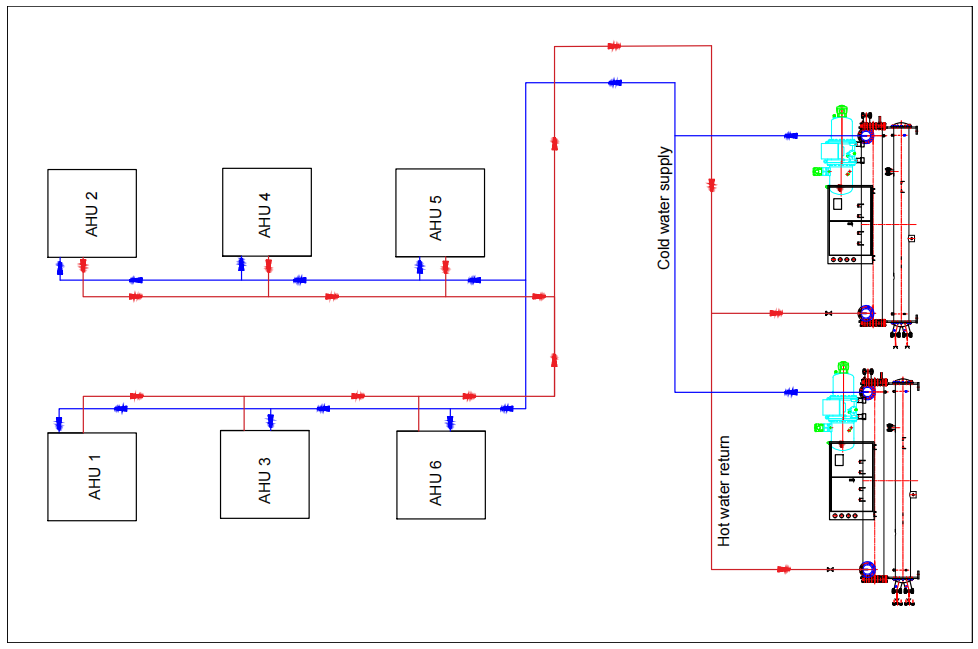

How Chiller works on AHU

Air Handling Units (AHUs) are an important component of HVAC systems that are responsible for circulating air throughout a building. In order to maintain a comfortable and healthy indoor environment, it’s important that the air is kept at the right temperature and humidity levels. This is where Kaydeli AHU chillers come in – they are designed to provide reliable cooling solutions for AHUs, ensuring that the air supplied to a building is comfortable and healthy.

How does a Kaydeli AHU chiller work?

A Kaydeli AHU chiller works by circulating chilled water through the AHU. The chiller contains a refrigeration cycle that is used to cool the water, which is then circulated through the AHU’s cooling coil. The cooling coil removes heat and moisture from the air that is passed over it, resulting in cool, dry air that is then supplied to the building’s HVAC system.

The refrigeration cycle in a Kaydeli AHU chiller typically includes four key components: a compressor, a condenser, an expansion valve, and an evaporator. The compressor is responsible for compressing the refrigerant gas, which raises its temperature and pressure. The high-pressure gas is then passed through a condenser, which removes heat from the gas and converts it into a high-pressure liquid.

The high-pressure liquid is then passed through an expansion valve, which reduces its pressure and temperature. The low-pressure liquid is then passed through an evaporator, where it absorbs heat from the water that is circulated through the chiller. The heat absorbed by the refrigerant is then carried away by the compressor, which starts the cycle over again.

The chiller’s microcomputer controller is responsible for regulating the temperature of the chilled water that is circulated through the AHU. The controller monitors the temperature of the chilled water and adjusts the operation of the chiller’s components as needed to maintain the desired temperature. The controller also includes safety features such as high and low-pressure protection, anti-freezing protection, and power-off protection to ensure safe and reliable operation.

The whole mechanism of the chiller in an AHU

The whole mechanism of a Kaydeli AHU chiller in an AHU involves several key components that work together to provide reliable cooling. The chiller itself is typically housed in a mechanical room or basement and is connected to the AHU by a series of pipes that circulate the chilled water.

The chiller’s compressor is typically driven by an electric motor and is responsible for compressing the refrigerant gas. The refrigerant gas is then passed through the condenser, which removes heat from the gas and converts it into a high-pressure liquid.

The high-pressure liquid is then passed through an expansion valve, which reduces its pressure and temperature. The low-pressure liquid is then passed through the evaporator, which absorbs heat from the water that is circulated through the chiller. The heat absorbed by the refrigerant is then carried away by the compressor, which starts the cycle over again.

The chiller’s microcomputer controller is responsible for monitoring and regulating the temperature of the chilled water that is circulated through the AHU. The controller adjusts the operation of the chiller’s components as needed to maintain the desired temperature, and includes safety features to ensure safe and reliable operation.

Overall, a Kaydeli AHU chiller is a reliable and efficient solution for cooling air in an AHU. By providing chilled water that is circulated through the AHU’s cooling coil, the chiller helps to maintain comfortable and healthy indoor environments for a wide range of applications.

For any kind of inquiries about the Kaydeli AHU chiller unit please feel free to contact us.

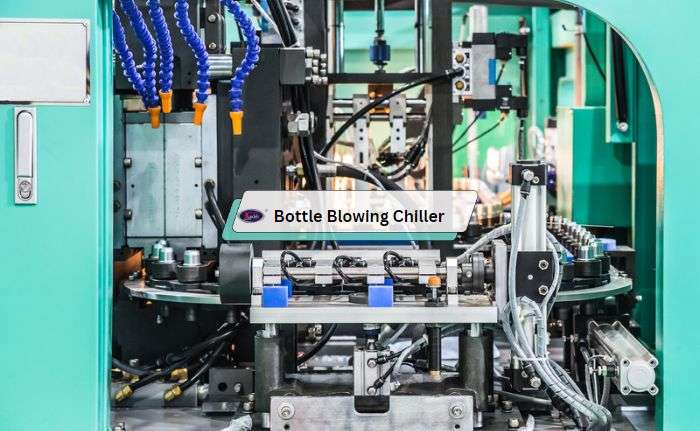

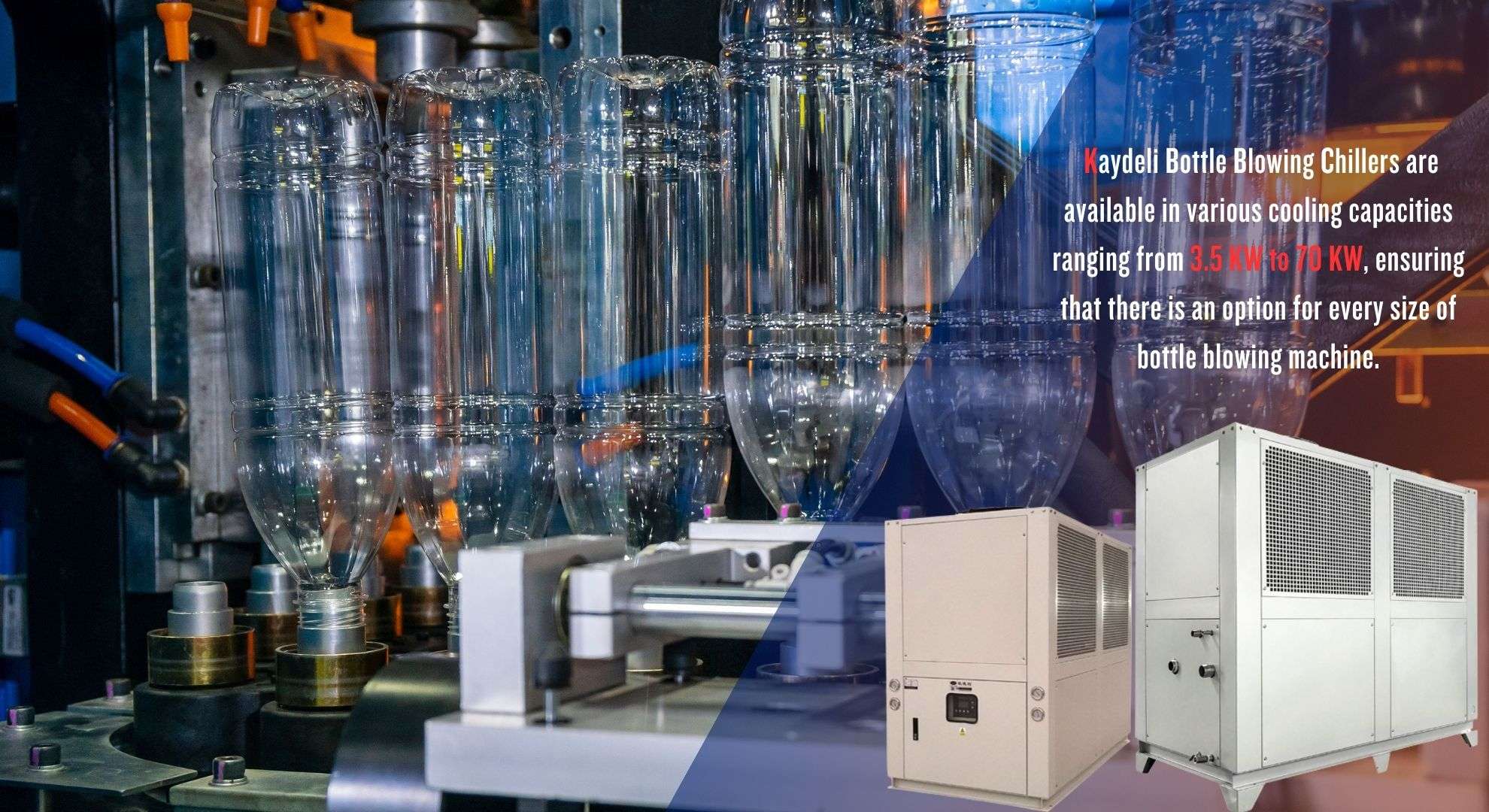

Enhance Your Bottle Blowing Process with Kaydeli Chiller

Bottle blowing is a manufacturing process used in the production of plastic bottles, where preforms or molds of plastic are heated and blown into the desired shape of the final product. The success of the bottle-blowing process depends on several factors, one of which is temperature control. To ensure consistent quality and efficiency in the bottle-blowing process, it is essential to have a reliable cooling system that can regulate the temperature of the plastic preforms.

Kaydeli is a leading manufacturer of industrial chillers, including those used in the bottle-blowing process. In this article, we will explore the features and benefits of Kaydeli bottle-blowing chillers.

Features of Kaydeli Bottle Blowing Chillers Kaydeli Bottle Blowing Chillers are designed to provide precise temperature control, reliability, and energy efficiency to the bottle-blowing process. Some of the key features of Kaydeli chillers include:

High Cooling Capacity: Kaydeli Bottle Blowing Chillers are available in various cooling capacities ranging from 3.5 KW to 70 KW, ensuring that there is an option for every size of the bottle-blowing machine.

Energy Efficiency: Kaydeli Bottle Blowing Chillers are equipped with world-famous efficient compressors like Danfoss, and Panasonic that help to reduce energy consumption and operating costs.

High-Quality Components: Kaydeli Bottle Blowing Chillers are built with high-quality components, such as compressors, evaporators, and condensers, that are designed for durability and reliability.

Precise Temperature Control: Kaydeli Bottle Blowing Chillers are equipped with microprocessor-based controllers that provide precise temperature control within +/- 0.5°C~1°C, ensuring consistent product quality.

User-Friendly Design: Kaydeli Bottle Blowing Chillers are designed with ease of use in mind, with features such as LCD displays, fault alarms, and remote control options for convenient operation and monitoring.

Benefits of Kaydeli Bottle Blowing Chillers The use of Kaydeli Bottle Blowing Chillers in the bottle-blowing process provides several benefits, including:

Improved Product Quality: The precise temperature control provided by Kaydeli Bottle Blowing Chillers ensures consistent product quality, resulting in better-looking, higher-quality bottles.

Increased Efficiency: Kaydeli Bottle Blowing Chillers can help to increase efficiency in the bottle-blowing process by reducing the cooling time required and increasing the number of bottles that can be produced in a given amount of time.

Cost Savings: Kaydeli Bottle Blowing Chillers are designed to be energy efficient, which can lead to cost savings in operating expenses over time.

Increased Equipment Lifespan: The use of Kaydeli Bottle Blowing Chillers can help to extend the lifespan of bottle-blowing machines by reducing the amount of wear and tear on the equipment.

Easy Maintenance: Kaydeli Bottle Blowing Chillers are designed for easy maintenance, with features such as removable filters and easy access to components for quick repairs.

Conclusion: Kaydeli Bottle Blowing Chillers are an excellent choice for any manufacturer looking to improve the quality and efficiency of their bottle-blowing process. With their high cooling capacity, energy efficiency, and precise temperature control, Kaydeli chillers can help to increase productivity, reduce operating costs, and improve the overall quality of the final product. Additionally, their user-friendly design and easy maintenance make them a convenient and reliable option for any bottle-blowing operation. If you are looking for any kinds of chillers for your project please, don’t hesitate to contact us.

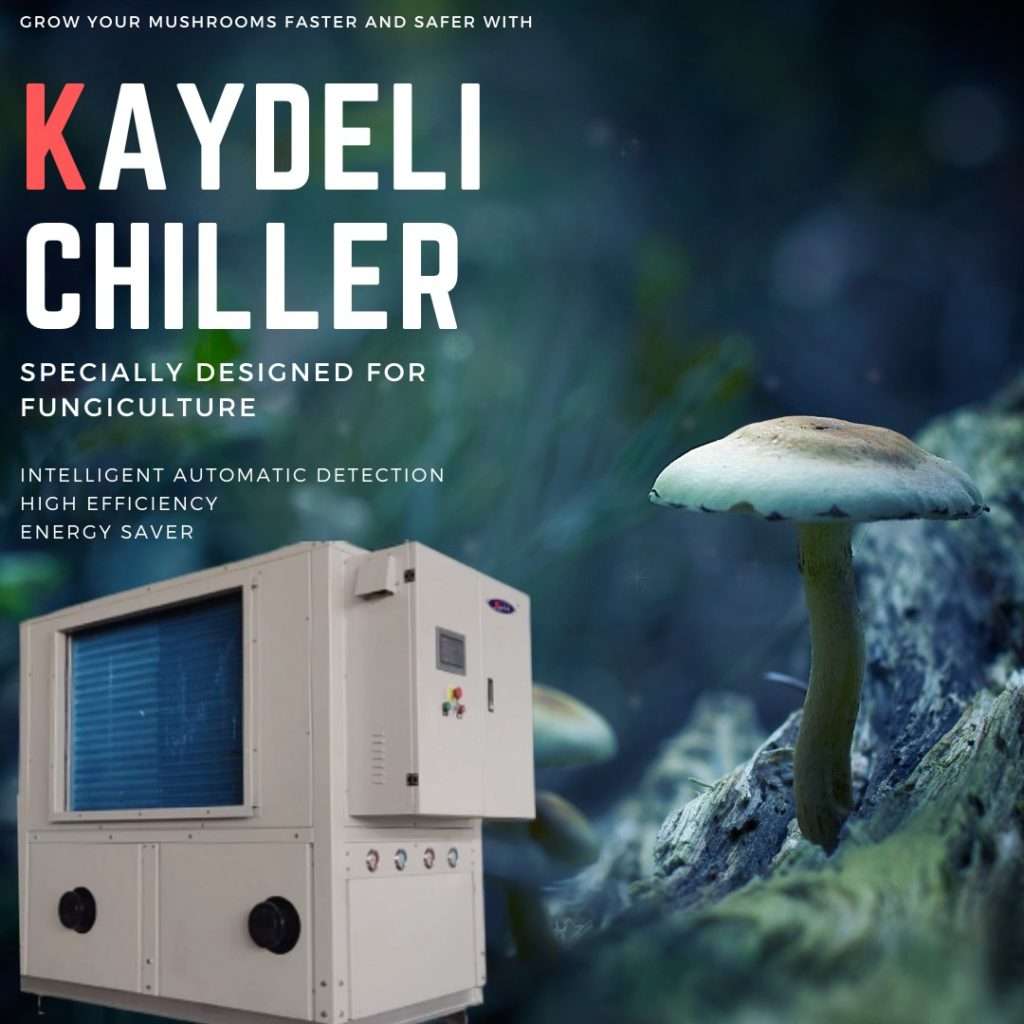

Give your mushroom firm a reliable system

Mushrooms are a popular and nutritious food item that is widely consumed around the world. They are low-calorie food and are a good source of vitamins, minerals, and antioxidants.

Growing mushrooms is a complex process, and the ideal temperature and humidity levels must be maintained throughout the growth cycle to produce high-quality mushrooms. One tool that can be instrumental in this process is Kaydeli’s mushroom chiller, which can precisely control the temperature of the mushroom farm.

In this article, we will discuss why it is necessary to use Kaydeli’s mushroom chiller in mushroom cultivation.

Maintaining the Ideal Temperature One of the critical factors in mushroom cultivation is maintaining the ideal temperature throughout the growing process. Different types of mushrooms have different temperature requirements, and it is essential to maintain the optimal temperature for each species.

The temperature of the mushroom farm should be kept at a constant level throughout the growing cycle, from the initial stage of mycelium growth to the fruiting stage. If the temperature fluctuates too much, the mushrooms can become stunted, develop abnormalities or even fail to grow all together.

Kaydeli’s mushroom chiller is specifically designed to maintain a stable temperature in the mushroom growing environment. The chiller uses advanced temperature control technology, allowing growers to set the temperature to a precise degree, and then maintain that temperature consistently throughout the growing process.

With Kaydeli’s mushroom chiller, growers can maintain the ideal temperature for each type of mushroom, resulting in better quality and higher yields.

Humidity: Regulating Humidity Levels In addition to temperature, maintaining the right humidity level is also critical to successful mushroom cultivation. High humidity levels can encourage mold and bacteria growth, while low humidity levels can cause the mushrooms to dry out and shrink.

Therefore, it is necessary to regulate the humidity levels in the mushroom-growing environment.

Kaydeli’s mushroom chiller can also control the humidity levels in the mushroom growing environment. The chiller’s advanced technology allows growers to set the humidity level precisely, which the chiller can then maintain consistently throughout the growing process. This ensures that the humidity level is kept at an optimal level, resulting in healthy, high-quality mushrooms.

Energy Efficiency: Another advantage of Kaydeli’s mushroom chiller is its energy efficiency. Traditional cooling systems can consume a significant amount of energy, leading to high electricity bills. However, Kaydeli’s mushroom chiller uses energy-efficient technology to regulate temperature and humidity levels. This leads to significant energy savings, resulting in lower operating costs and a smaller carbon footprint.

Conclusion: In conclusion, using Kaydeli’s mushroom chiller is necessary for successful mushroom cultivation. The chiller’s advanced temperature and humidity control technology allows growers to maintain the ideal growing environment for each type of mushroom, resulting in better quality and higher yields.

Moreover, Kaydeli’s mushroom chiller is energy-efficient, resulting in lower operating costs and a smaller carbon footprint.

If you are considering starting a mushroom farm, investing in Kaydeli’s mushroom chiller is a wise decision that can pay off in the long run. Please contact us if you want to learn more about Mushroom chillers.

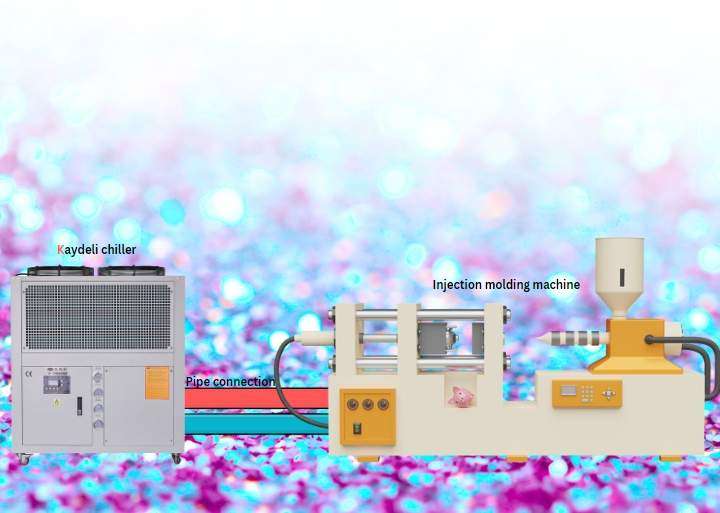

Why Chillers are important in Plastic Molding Industry

The plastic molding industry is a critical sector that produces a wide range of plastic products used in various industries such as automotive, aerospace, medical, consumer goods, and packaging. In the plastic molding process, a chiller is an essential piece of equipment that plays a crucial role in maintaining the quality and consistency of the final product. In this article, we will discuss the essential need for a chiller in the plastic molding industry.

What is a Plastic Molding Chiller?

A plastic molding chiller is a refrigeration system that cools water or other fluids to a specific temperature, which is then used to cool the molds or equipment during the manufacturing process. In short, A chiller is a machine that cools a liquid or air using a refrigeration cycle. Injection molding is the most common plastic molding process used to produce complex and high-volume plastic parts.

How does a Chiller work in Plastic Molding?

The plastic molding process involves injecting molten plastic material into a mold cavity and then cooling it to solidify and form the final product. A chiller is used to cool the mold and the plastic material during the injection molding process.

The chiller works by circulating a coolant or refrigerant through the chiller unit and then into the mold cavity to remove the heat generated during the molding process. The coolant is then recirculated through the chiller to remove the heat and maintain a consistent temperature in the mold.

Why is a Chiller Essential in Plastic Molding?

A chiller is essential in the plastic molding process for several reasons:

Without a chiller, the plastic molding process would be significantly affected.

Consistency: The use of a chiller ensures that the mold and the plastic material are consistently cooled during the molding process. This consistency ensures that the final product is of high quality and meets the required specifications.

Faster Molding: A chiller can cool the mold and plastic material faster, reducing the overall cycle time for the molding process. This faster cooling time enables a higher production rate and reduces the cost per unit.

Prevention of Defects: The use of a chiller helps prevent defects in the final product caused by uneven cooling, warping, and shrinkage. These defects can be costly to fix and may result in rejected products, lost time, and increased production costs.

Longer Equipment Life: The use of a chiller helps prolong the life of the mold and the injection molding machine. The consistent cooling provided by the chiller reduces stress and wear on the equipment, resulting in less maintenance and repair costs over time.

In conclusion, the chiller is an essential piece of equipment in the plastic molding industry. Its use ensures that the final product is of high quality, consistent, and free from defects. The chiller also reduces the cycle time, increasing production rates and reducing the cost per unit. The use of a chiller is a sound investment for any plastic molding business, as it helps prolong the life of the equipment and reduces the overall cost of production.

Contact us:

If you have any further questions or would like to learn more about how our company can help you with your chiller needs, please do not hesitate to contact us.

Our team of experts has years of experience in the field and can provide you with customized solutions to fit your specific requirements. We offer a range of chiller options, including water-cooled and air-cooled chillers, to meet the unique needs of your operation.

Green Refrigerants in Chillers to Reduce Emissions

Introduction: What is Green Refrigerant and Why is it Important in Industrial Chillers?

Green refrigerants are becoming increasingly important in industrial chillers as they help reduce the impact of climate change. Refrigerants are used in HVAC systems to keep a building cool and are known to be the largest contributor to greenhouse gas emissions. Green refrigerants, like hydrofluoroolefins (HFOs) and hydrochlorofluorocarbons (HCFCs), have a much lower global warming potential than traditional refrigerants, making them a much more sustainable solution for cooling. Industrial chillers that use green refrigerants can not only help reduce carbon emissions but also reduce energy costs.

How Green Refrigerants Can Help Decrease Emissions from Industrial Chillers

Industrial chillers are a major source of greenhouse gas emissions, contributing to global warming and ozone depletion. The use of green refrigerants, such as natural refrigerants or hydrocarbon refrigerants, can help reduce these emissions and protect the environment. Natural refrigerants have a much lower ozone depletion potential (ODP) and global warming potential (GWP) than traditional synthetic refrigerants. They are also more efficient, leading to lower energy consumption and cost savings for businesses. By switching to green refrigerants, businesses can reduce their environmental impact while still providing reliable cooling solutions for their customers.

The Benefits of Using Green Refrigerants in Industrial Cooling & Heating Systems

With the world’s growing demand for energy, green refrigerants are becoming increasingly important in industrial cooling and heating systems. Green refrigerants are non-toxic, non-ozone-depleting chemicals that can replace traditional hydrofluorocarbons (HFCs) in industrial cooling and heating systems. Green refrigerants offer numerous benefits such as improved energy efficiency, lower carbon emissions, and improved safety.

What Are the Challenges Involved With Implementing Green Refrigerants in Industrial Chillers?

With the ever-increasing environmental concerns, businesses are looking for ways to reduce their carbon footprint by implementing green refrigerants in their industrial chillers. This switch to natural refrigerants has a lot of benefits, however, some challenges need to be taken into consideration before making the switch. These challenges include assessing the environmental impacts of using green refrigerants and ensuring that all safety considerations are met when using natural refrigerants.

How to Transition Towards a Sustainable Choice

With the world’s resources rapidly depleting and global warming becoming a more pressing issue, we must make a conscious effort to transition toward sustainable choices. We must take steps to reduce our carbon footprint and ensure that our actions do not harm the environment. Making the switch to sustainable options is not only good for the planet but also beneficial for businesses as it can help them save money in the long run. Kaydeli is one of the industrial chiller manufacturers that offer and suggest to use of environment-friendly refrigerants. Let’s all work together to make the world a better place.

Some lists of eco-friendly refrigerant