Keep Your Pool and Spa Cool with Kaydeli Chillers

Swimming pools and spas are a great way to relax and enjoy the outdoors, especially during the warmer months of the year. However, as the temperature rises, so does the temperature of the water, making it less comfortable to swim or soak in. This is where the swimming pool and spa chillers come in.

A swimming pool and spa chiller is a type of chiller that is designed to cool the water in your pool and spa to a comfortable temperature. These chillers work by circulating the water through a heat exchanger, which is cooled by either air or water. The cooled water is then returned to the pool and spa, lowering the temperature of the water.

There are different types of swimming pool and spa chillers available, including air-cooled chillers, water-cooled chillers, and dual-temperature chillers.

Here are some more details about the types of chillers and which one may be best for your needs:

Air-cooled chillers:

Air-cooled chillers are the most common type of chiller for swimming pools and spas. They work by using a fan to blow air across a heat exchanger, which cools the water. These chillers are more affordable and easier to install than water-cooled chillers, but they are also less efficient and may not be suitable for larger pools or spas.

Water-cooled chillers:

Water-cooled chillers use a water source, such as a nearby lake or pond, to cool the water. These chillers are more efficient than air-cooled chillers, making them ideal for larger pools or spas. However, they are also more expensive to install and require access to a water source like a water tower.

Dual-temperature chillers:

Dual-temperature chillers are designed to cool the pool and spa simultaneously. They are ideal for those who have both and want to maintain different water temperatures for each. These chillers are a bit more expensive than single-temperature chillers as they require a heating device and some more equipment, but they offer the convenience of cooling both the pool and spa at the same time.

Low-temperature chillers:

Low-temperature chillers are designed to cool water to temperatures below 60°F (15.5°C) and are ideal for those who have ice rinks or other applications that require very cold water. These chillers are more expensive and require special considerations, such as a glycol solution to prevent freezing.

When choosing a chiller, it’s essential to consider the size of your pool or spa, your budget, and your specific needs. An air-cooled chiller may be the best choice if you have a small residential pool or spa. If you have a larger commercial pool or spa, a water-cooled chiller may be more efficient. If you have both a pool and spa and want to cool both, a dual-temperature chiller may be the best option.

Kaydeli is an industrial chiller manufacturing company that specializes in producing high-quality chillers for various applications, including swimming pools and spas. They offer a wide range of chillers, including air-cooled, water-cooled, and dual-temperature chillers, to suit your specific needs.

Kaydeli’s chillers are made from high-quality materials and are designed to be energy-efficient, durable, and easy to maintain. They offer a variety of features, such as digital temperature control, automatic shut-off, and quiet operation, to make using their chillers convenient and hassle-free.

Whether you have a small residential pool or a large commercial spa, Kaydeli can help you find the right chiller for your needs. Our team of experts can help you choose the right chiller based on the size of your pool or spa, your budget, and your specific requirements.

In conclusion, swimming pool and spa chillers are an essential investment for anyone who wants to enjoy their pool or spa throughout the year, regardless of the temperature.

Kaydeli is an industrial chiller manufacturing company that offers a wide range of chillers, including air-cooled, water-cooled, and dual-temperature chillers, to help you keep your pool and spa at a comfortable temperature.

Contact Kaydeli today to find the right chiller for your needs.

Why water cooled chillers are important?

Water-cooled chillers play a critical role in the cooling industry, providing precise and efficient cooling for a wide range of industrial applications. These systems use water as a coolant to remove heat from processes and equipment, making them an ideal choice for large-scale cooling needs.

One of the key benefits of water-cooled chillers is their energy efficiency. Compared to air-cooled chillers, water-cooled systems use water as a more efficient heat transfer medium, resulting in lower energy consumption and reduced operating costs.

This makes them a cost-effective solution for cooling large industrial processes, such as data centers, manufacturing plants, and hospitals.

Another benefit of water-cooled chillers is their quiet operation. Unlike air-cooled chillers, which require large fans to circulate air, water-cooled systems operate quietly, making them ideal for use in noise-sensitive environments, such as hospitals, schools, and residential areas.

Water-cooled chillers also have a longer lifespan than air-cooled chillers. Because they are not exposed to harsh outdoor conditions, such as extreme temperatures, rain, and snow, they are less prone to wear and tear.

Hence, they are easier to maintain and repair, as their components are located indoors and are not subject to weather-related damage.

Water-cooled chillers are also highly customizable, making them a versatile choice for many different cooling needs. They can be designed to handle a wide range of cooling loads and can be customized to meet specific requirements, such as temperature control and humidity control.

For industrial settings, precise temperature control is critical for ensuring optimal product quality and equipment performance. Water-cooled chillers provide greater thermal stability and consistency than air-cooled systems, allowing for improved process control and reduced downtime.

Water-cooled chillers are widely used in a variety of industries, from food and beverage production to pharmaceutical manufacturing to HVAC systems. In the food and beverage industry, water-cooled chillers are used to maintain precise temperatures during the fermentation process of beer and wine production, as well as in other food processing applications.

As for the pharmaceutical industry, water-cooled chillers are used to regulate the temperature of sensitive equipment and samples, ensuring accuracy and reliability in research and testing.

In HVAC systems, water-cooled chillers are used to cool buildings, providing efficient and consistent temperature control.

One of the primary advantages of water-cooled chillers is their ability to handle large cooling loads. They are capable of providing cooling to multiple processes and equipment simultaneously, making them a versatile and reliable choice for industrial applications.

Additionally, water-cooled chillers can be designed to operate with a variety of different refrigerants, allowing them to meet the specific needs of different applications.

Water-cooled chillers are also a more sustainable choice compared to air-cooled chillers. Because they use water as a coolant, they have a smaller environmental footprint and produce fewer greenhouse gas emissions.

In conclusion, water-cooled chillers are an important component of the cooling industry, providing efficient and reliable cooling for large-scale industrial processes and equipment. Their energy efficiency, quiet operation, longer lifespan, and customizable design make them a versatile and cost-effective solution for a wide range of cooling needs.

Contact Us: If you have any questions or would like to learn more about water-cooled chillers, feel free to contact us. Our team of experts is ready to provide you with the information you need to make the best cooling decisions for your industrial application.

Why Glycol Chillers Are For High Precision Cooling

Glycol chillers are used in various projects across different industries for their ability to maintain precise temperature control. They work by circulating a mixture of water and glycol through a closed-loop system.

The chilled mixture is then used to cool down the process equipment, which helps maintain a stable temperature and prevent overheating.

For example, in the food and beverage industry, glycol chillers are commonly used to maintain the temperature of fermenters, which are used to make beer, wine, and other alcoholic beverages. They are also used in dairy production to keep milk and cheese at the right temperature.

In the pharmaceutical industry, glycol chillers are used in the manufacturing of drugs and vaccines.

They are used to keep the temperature stable during the production process, which is crucial for ensuring the quality and efficacy of the final product.

In the plastics industry, glycol chillers are used to cool down molds used for injection molding, extrusion, and blow molding processes. These processes can generate a lot of heat, and the use of glycol ensures that the molds remain at the correct temperature, which helps maintain product quality and prevent damage to the equipment.

In the HVAC industry, glycol chillers are used to cool down the water used in air conditioning systems. This helps regulate the temperature and humidity of indoor spaces, ensuring comfort for occupants.

Overall, glycol chillers are a versatile solution for maintaining precise temperature control in various projects and industries. They offer reliability, efficiency, and ease of use, making them a popular choice for businesses that require temperature-sensitive processes.

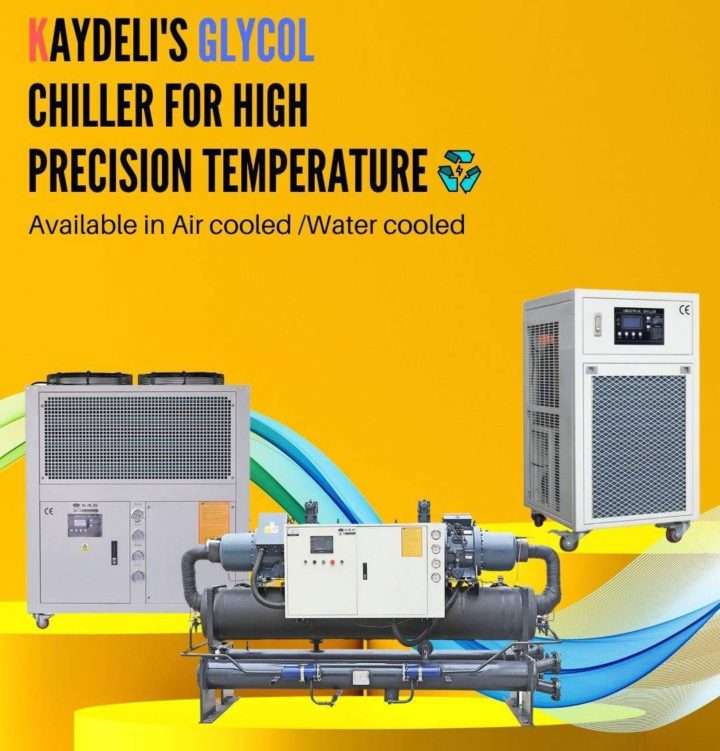

Kaydeli is a leading manufacturer of high-quality Glycol chillers, which are widely used in various industries, including food and beverage, chemical, and pharmaceuticals.

These chillers are known for their high efficiency, reliability, and ease of use, making them a popular choice for businesses that require precise temperature control for their processes.

Glycol chillers work by circulating a mixture of water and glycol through a closed-loop system. The chilled mixture is then used to cool down the process equipment, which helps maintain a stable temperature and prevent overheating. The use of glycol also prevents freezing, making it a versatile coolant for a wide range of applications.

One of the key features of Kaydeli’s Glycol chillers is their high efficiency. These chillers use advanced compressors and heat exchangers to deliver maximum cooling performance while minimizing energy consumption.

This not only saves businesses money on their energy bills but also reduces their carbon footprint, making them a sustainable choice for environmentally conscious organizations.

Another advantage of Kaydeli’s Glycol chillers is their reliability. These chillers are built to last, with high-quality components and robust construction that can withstand even the most demanding environments. They are also designed for easy maintenance, with accessible components and user-friendly controls that make it simple to diagnose and fix any issues.

Kaydeli’s Glycol chillers are also highly customizable, with a wide range of options to suit different needs and applications. They are available in a variety of sizes and capacities, with multiple compressor configurations and control options to choose from. This allows businesses to select a chiller that is perfectly tailored to their requirements, whether they need to cool a small laboratory setup or a large-scale industrial process.

In conclusion, Kaydeli’s Glycol chillers are a reliable, efficient, and versatile solution for businesses that require precise temperature control for their processes. With their high-quality construction, user-friendly controls, and wide range of customization options, they are an excellent investment for organizations that value quality and efficiency.

If you have any questions regarding Kaydeli chillers please, feel free to contact us.