In New Zealand: The Secrets to Safe and High-Quality Milk

Milk Production Cooling Project, Nutrizone Limited (New Zealand)

Industrial chillers play a pivotal role in the dairy production industry, ensuring the quality and safety of dairy products. With stringent temperature requirements, maintaining optimal cooling conditions is essential throughout the production process. Industrial chillers are used to cool milk, cream, and other dairy ingredients, preserving their freshness and preventing potential spoilage. These chillers also aid in the production of dairy products like yogurt, cheese, and ice cream, enabling precise temperature control during fermentation, aging, and freezing processes. By utilizing reliable chillers, dairy producers can uphold product integrity, extend shelf life, and meet strict regulatory standards, ultimately delivering high-quality and safe dairy products to consumers worldwide.

In this article, we will discuss the industry and the application of the Kaydeli chiller in the yogurt and other dairy production process. We hope it will be helpful for industry partners to choose chillers.

Yogurt is too common in our daily life! In milk production, the chiller is one of the essential pieces of equipment, usually used as shared equipment, and is closely related to the equipment in all related production links of yogurt.

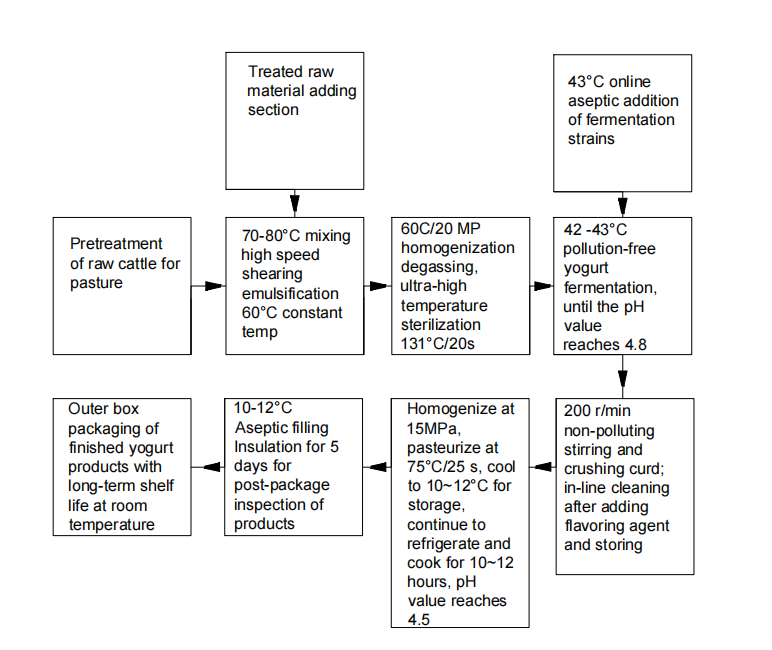

Yogurt production process

New Zealand Nutrizone Limited is a New Zealand food group specializing in the production of milk products and food. Through industry partners, they found the Kaydeli Foreign Trade Department, which is also concerned about the Kaydeli brand chiller, Because there were many refrigeration projects for milk, food, and beverages are been supplied with Kaydeli industrial chillers.

For example, Shandong Dongying Milk Cooling Project, KEKO (Malaysia), the Coca-Cola beverage production project in Huizhou, etc.

They shared the specific parameter requirements of the chiller, not only to meet the production needs but also to meet the safety and health requirements, to be reliable in operation and economical in cost.

According to the specific needs of customers, our engineering team learned about the milk production process of the customer’s factory and advised two air-cooled twin-screw chillers, KDCS-160LLA and KDCS-180DLA.

The production equipment is mainly composed of raw milk storage and pretreatment equipment, mixing treatment equipment, ultra-high temperature sterilization equipment, yogurt fermentation equipment, yogurt pasteurization equipment, yogurt aseptic filling equipment, CIP cleaning equipment, etc.

The chillers are used in milk production and can be used as the cold source of the low-temperature cooling system to control the temperature of the production process and control the growth of bacteria within a certain speed. The low-temperature chiller can quickly cool down and ensure a suitable temperature environment for milk production.

Here is the flow chart below of the dairy production,

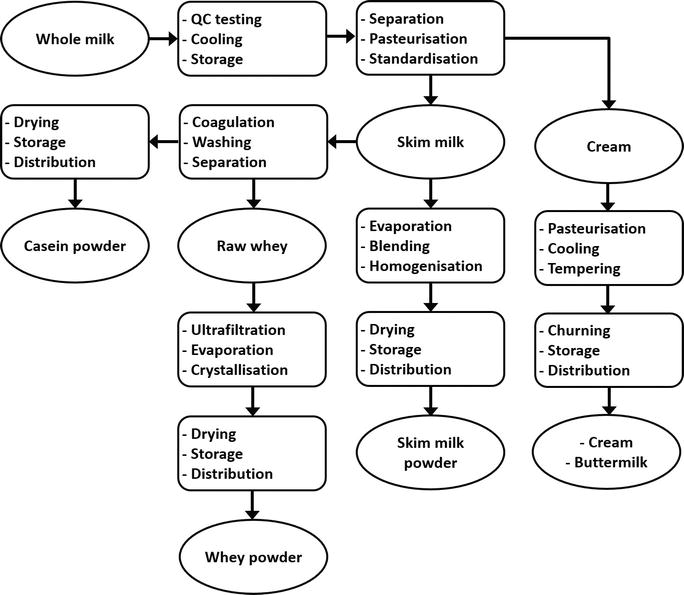

Dairy production process

In milk processing and production, there are many temperature links involved. One of the most typical applications is low temperature. In the process of the milk collection system, for the cooling process of fresh milk, the fresh milk needs to be quickly cooled to Below 1~4 degrees, otherwise it will be detrimental to the quality of milk.

In the low-temperature process of cooling milk, the equipment sends milk to the other side of the refrigeration system through stainless steel refrigeration equipment (customized food-grade materials), and exchanges heat with frozen water to achieve rapid cooling to the temperature required by the process.

The Kaydeli chiller research and development team fully understands the importance of milk cooling, and provides a set of more practical, energy-saving, and convenient refrigeration engineering solutions, which have the following points:

Low refrigerant losses: Kaydeli chillers are dedicated to reducing refrigerant loss to the environment, making our equipment more productive and efficient.

Less energy to operate: Kaydeli chillers use less energy and our economical solutions reduce energy consumption, reducing operating costs and increasing production capacity for you.

Maintenance: The refrigerating unit is easier to maintain. By using a heat exchanger that is easy to clean, the maintenance time is reduced, which saves huge manpower, material, and financial resources for the milk enterprise.

KDCS-160LLA, and KDCS-180DLA, with temperature adjustable ranges of (7°C~30°C), and (0℃~30°C).

The following introduces the characteristics of the Kaydeli chiller, which is used in the milk cooling system:

The general cooling system is composed of an air-cooled condenser unit, refrigeration compressor, evaporator, electric control system, etc. According to environmental factors such as outdoor temperature and humidity, an air-cooled or water-cooled chiller system (depending on the requirements) with appropriate parameters can be configured to reduce the temperature of the milk through cooling to achieve the temperature of the milk in the milk cooling process.

A plate heat exchanger cools the milk before it reaches the bulk milk cooler. Dairy farms can save up to 30% on milk chilling costs with Kaydeli.

The screw compressor has high refrigeration efficiency, and adopts the Hanbell brand, Although the price is higher than traditional compressors, the efficiency is increased by about 20%, and there are fewer moving parts, which greatly increases the life of the compressor.

After installation and commissioning, the equipment has been working normally, and the cooling task of milk production has been successfully completed.

Kaydeli chiller is not only used in the process of milk collection system but also in the cooling process of pasteurization (about 1-8 degrees); it can also be used for cooling in the UHT process section.