Enhance Your Bottle Blowing Process with Kaydeli Chiller

Bottle blowing is a manufacturing process used in the production of plastic bottles, where preforms or molds of plastic are heated and blown into the desired shape of the final product. The success of the bottle-blowing process depends on several factors, one of which is temperature control. To ensure consistent quality and efficiency in the bottle-blowing process, it is essential to have a reliable cooling system that can regulate the temperature of the plastic preforms.

Kaydeli is a leading manufacturer of industrial chillers, including those used in the bottle-blowing process. In this article, we will explore the features and benefits of Kaydeli bottle-blowing chillers.

Features of Kaydeli Bottle Blowing Chillers Kaydeli Bottle Blowing Chillers are designed to provide precise temperature control, reliability, and energy efficiency to the bottle-blowing process. Some of the key features of Kaydeli chillers include:

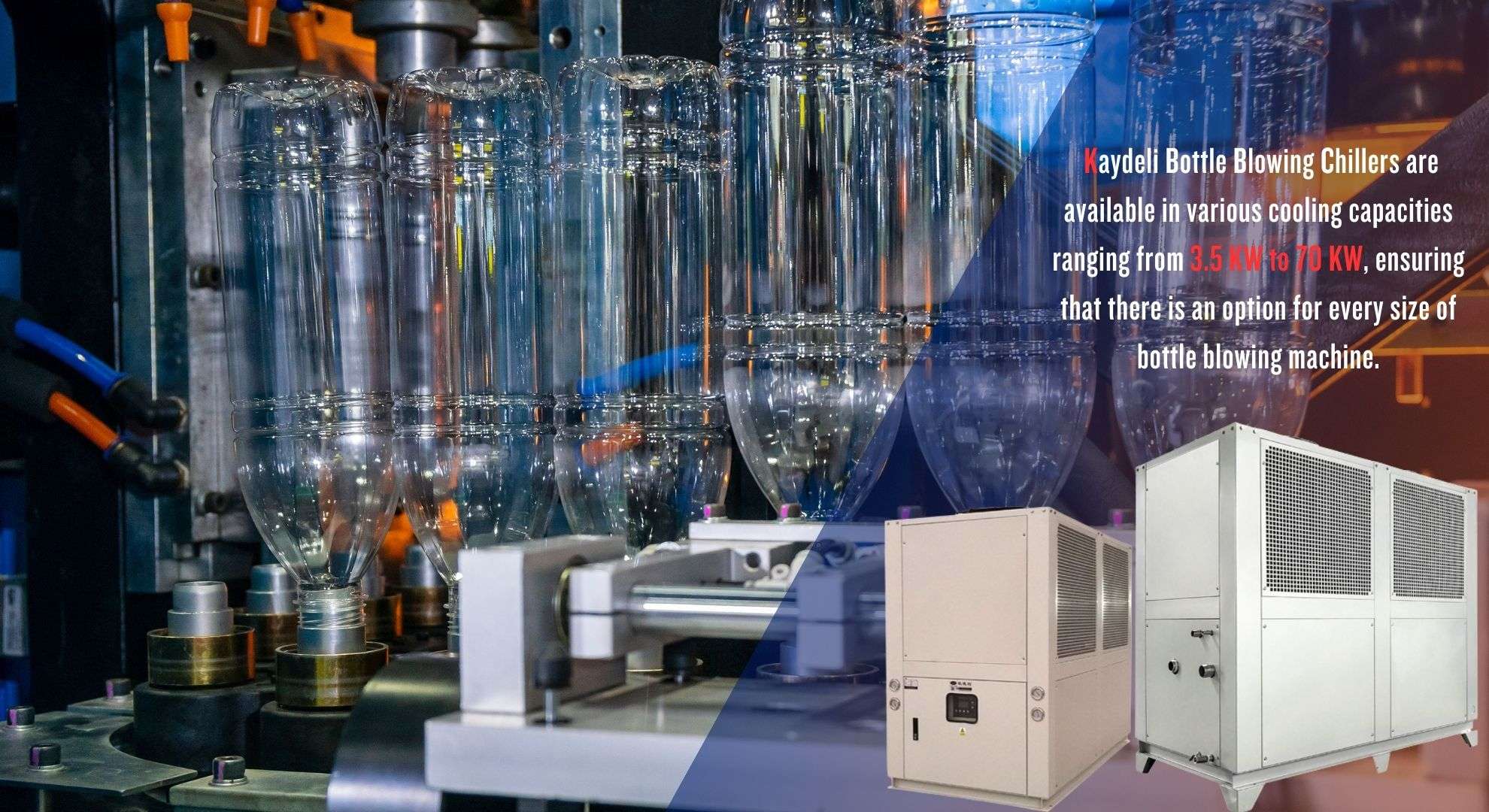

High Cooling Capacity: Kaydeli Bottle Blowing Chillers are available in various cooling capacities ranging from 3.5 KW to 70 KW, ensuring that there is an option for every size of the bottle-blowing machine.

Energy Efficiency: Kaydeli Bottle Blowing Chillers are equipped with world-famous efficient compressors like Danfoss, and Panasonic that help to reduce energy consumption and operating costs.

High-Quality Components: Kaydeli Bottle Blowing Chillers are built with high-quality components, such as compressors, evaporators, and condensers, that are designed for durability and reliability.

Precise Temperature Control: Kaydeli Bottle Blowing Chillers are equipped with microprocessor-based controllers that provide precise temperature control within +/- 0.5°C~1°C, ensuring consistent product quality.

User-Friendly Design: Kaydeli Bottle Blowing Chillers are designed with ease of use in mind, with features such as LCD displays, fault alarms, and remote control options for convenient operation and monitoring.

Benefits of Kaydeli Bottle Blowing Chillers The use of Kaydeli Bottle Blowing Chillers in the bottle-blowing process provides several benefits, including:

Improved Product Quality: The precise temperature control provided by Kaydeli Bottle Blowing Chillers ensures consistent product quality, resulting in better-looking, higher-quality bottles.

Increased Efficiency: Kaydeli Bottle Blowing Chillers can help to increase efficiency in the bottle-blowing process by reducing the cooling time required and increasing the number of bottles that can be produced in a given amount of time.

Cost Savings: Kaydeli Bottle Blowing Chillers are designed to be energy efficient, which can lead to cost savings in operating expenses over time.

Increased Equipment Lifespan: The use of Kaydeli Bottle Blowing Chillers can help to extend the lifespan of bottle-blowing machines by reducing the amount of wear and tear on the equipment.

Easy Maintenance: Kaydeli Bottle Blowing Chillers are designed for easy maintenance, with features such as removable filters and easy access to components for quick repairs.

Conclusion: Kaydeli Bottle Blowing Chillers are an excellent choice for any manufacturer looking to improve the quality and efficiency of their bottle-blowing process. With their high cooling capacity, energy efficiency, and precise temperature control, Kaydeli chillers can help to increase productivity, reduce operating costs, and improve the overall quality of the final product. Additionally, their user-friendly design and easy maintenance make them a convenient and reliable option for any bottle-blowing operation. If you are looking for any kinds of chillers for your project please, don’t hesitate to contact us.