Temperature Control System for Crystal Growth Furnace

What is a crystal growth furnace system?

A crystal growth furnace system is a machine used to grow crystals in a controlled environment. It typically consists of a furnace, which heats the material to the desired temperature, and a chamber where the crystal growth occurs. The system is designed to maintain specific temperature, pressure, and atmospheric conditions to ensure optimal crystal growth. These systems are widely used in the semiconductor, electronics, and materials science industries.

How does it work?

The working principle of a crystal growth furnace system is based on the controlled heating and cooling of a material to promote crystal growth. As mentioned earlier the system typically consists of a furnace, which heats the material to a high temperature, and a chamber where the crystal growth occurs. The material is melted and then slowly cooled under controlled conditions to promote the formation of a crystal lattice structure. The rate of cooling and other environmental factors such as pressure and gas composition can be adjusted to optimize the crystal growth process. Once the crystal has formed, it can be harvested and used for various applications.

Why a chiller is required for the process?

A chiller is required in a crystal growth furnace system to maintain a stable temperature within the system. The furnace heats the material to a high temperature, but it is important to cool the surrounding environment to prevent unwanted reactions and maintain a stable temperature for crystal growth. A chiller circulates a coolant, typically water, through the system to remove excess heat and maintain a stable temperature. The temperature of the coolant can be adjusted to control the temperature of the system, allowing for precise control of the crystal growth process. Without a chiller, it would be difficult to maintain a stable temperature and optimize crystal growth.

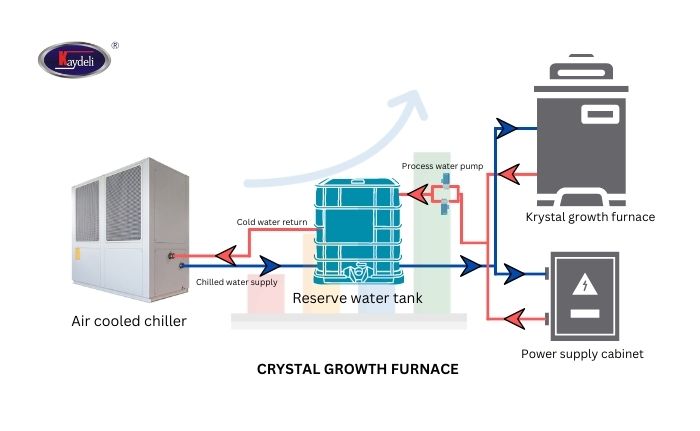

Here is one of our recent projects for an African crystal growth company.

In this project, Kaydeli used two of their air-cooled chillers KC-040TB and KC-050 TB to accomplish the project.

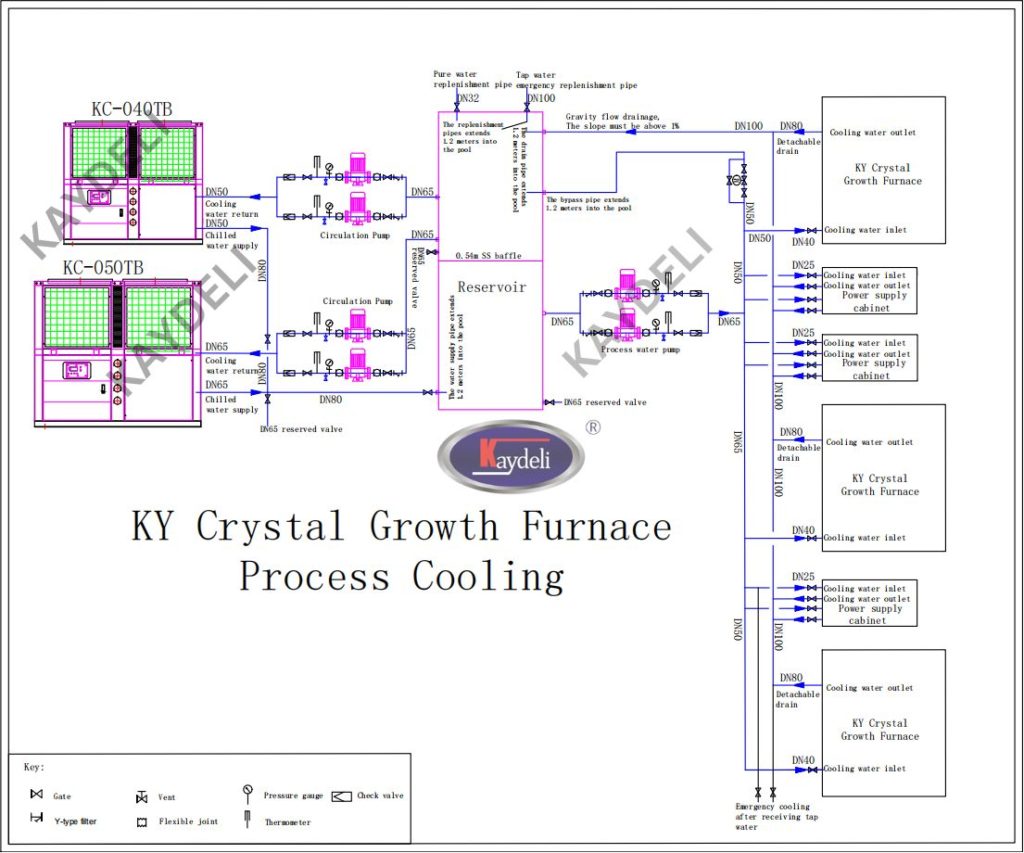

A total of five crystal growth furnaces are installed in this process, three KY crystal growth furnaces, and two GT crystal growth furnaces. The maximum production load operation does not exceed three crystal growth furnaces, and each cycle corresponds to the maintenance of different crystal growth furnaces.

The cooling water demand for a single unit of KY crystal growth furnace equipment is: 6m³/h, the constant temperature of the cooling water supply is 28°C±1°C, and the water inlet pressure of the crystal growth furnace is 0.2MPa-0.22MPa. The gravity flow returns to water, and the water inlet pressure of the power cabinet 0.2MPa-0.3MPa. The outlet water temperature rises by 5~7°C.

Here is the design of a set of cooling circulating water systems, using two air-cooled industrial chillers to cool down the normal temperature water in the 12 cubic reservoirs to the set temperature, and then the cold water in the reservoir is delivered to the crystal growth furnace equipment by the process water pump.

Two air-cooled industrial chillers are selected, one with a cooling capacity of 113.1KW (the other one has a cooling capacity of 141.4KW), an overall unit composed of four compressors, four independently operating refrigeration systems, process water pumps, air conditioning circulation pumps, and, centrifugal pumps. The material of the water supply and return pipes is 304 stainless steel(SS), and each device is equipped with 304 stainless steel (SS) valves. The air-cooled industrial chiller integrates the refrigeration system, water tank, and water pump for easy use and operation. The unit is compact and occupies a small area. It can be used when it is connected to water and electricity.

Intelligent control, using a high-precision LCD digital controller, can intuitively and accurately measure the outlet water temperature, the operation panel can intuitively display the operation and fault status of the compressor, water pump, and refrigeration system at a glance. Only pressing the start and stop buttons can run the equipment automatically. Simple operation and convenience.

Please feel free to contact Kaydeli for any kind of support in this field as well as for any Industrial chiller requirements.

Keep Your Pool and Spa Cool with Kaydeli Chillers

Swimming pools and spas are a great way to relax and enjoy the outdoors, especially during the warmer months of the year. However, as the temperature rises, so does the temperature of the water, making it less comfortable to swim or soak in. This is where the swimming pool and spa chillers come in.

A swimming pool and spa chiller is a type of chiller that is designed to cool the water in your pool and spa to a comfortable temperature. These chillers work by circulating the water through a heat exchanger, which is cooled by either air or water. The cooled water is then returned to the pool and spa, lowering the temperature of the water.

There are different types of swimming pool and spa chillers available, including air-cooled chillers, water-cooled chillers, and dual-temperature chillers.

Here are some more details about the types of chillers and which one may be best for your needs:

Air-cooled chillers:

Air-cooled chillers are the most common type of chiller for swimming pools and spas. They work by using a fan to blow air across a heat exchanger, which cools the water. These chillers are more affordable and easier to install than water-cooled chillers, but they are also less efficient and may not be suitable for larger pools or spas.

Water-cooled chillers:

Water-cooled chillers use a water source, such as a nearby lake or pond, to cool the water. These chillers are more efficient than air-cooled chillers, making them ideal for larger pools or spas. However, they are also more expensive to install and require access to a water source like a water tower.

Dual-temperature chillers:

Dual-temperature chillers are designed to cool the pool and spa simultaneously. They are ideal for those who have both and want to maintain different water temperatures for each. These chillers are a bit more expensive than single-temperature chillers as they require a heating device and some more equipment, but they offer the convenience of cooling both the pool and spa at the same time.

Low-temperature chillers:

Low-temperature chillers are designed to cool water to temperatures below 60°F (15.5°C) and are ideal for those who have ice rinks or other applications that require very cold water. These chillers are more expensive and require special considerations, such as a glycol solution to prevent freezing.

When choosing a chiller, it’s essential to consider the size of your pool or spa, your budget, and your specific needs. An air-cooled chiller may be the best choice if you have a small residential pool or spa. If you have a larger commercial pool or spa, a water-cooled chiller may be more efficient. If you have both a pool and spa and want to cool both, a dual-temperature chiller may be the best option.

Kaydeli is an industrial chiller manufacturing company that specializes in producing high-quality chillers for various applications, including swimming pools and spas. They offer a wide range of chillers, including air-cooled, water-cooled, and dual-temperature chillers, to suit your specific needs.

Kaydeli’s chillers are made from high-quality materials and are designed to be energy-efficient, durable, and easy to maintain. They offer a variety of features, such as digital temperature control, automatic shut-off, and quiet operation, to make using their chillers convenient and hassle-free.

Whether you have a small residential pool or a large commercial spa, Kaydeli can help you find the right chiller for your needs. Our team of experts can help you choose the right chiller based on the size of your pool or spa, your budget, and your specific requirements.

In conclusion, swimming pool and spa chillers are an essential investment for anyone who wants to enjoy their pool or spa throughout the year, regardless of the temperature.

Kaydeli is an industrial chiller manufacturing company that offers a wide range of chillers, including air-cooled, water-cooled, and dual-temperature chillers, to help you keep your pool and spa at a comfortable temperature.

Contact Kaydeli today to find the right chiller for your needs.

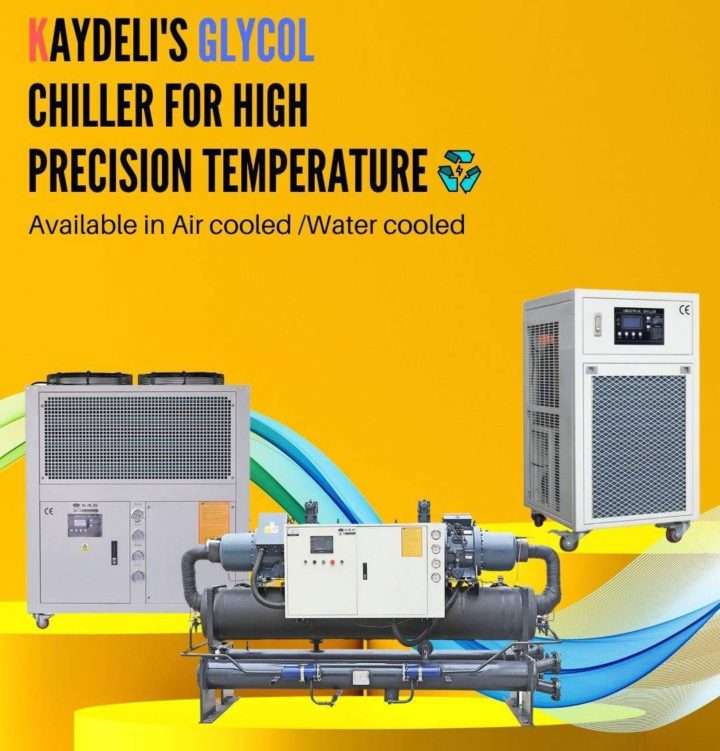

Why Glycol Chillers Are For High Precision Cooling

Glycol chillers are used in various projects across different industries for their ability to maintain precise temperature control. They work by circulating a mixture of water and glycol through a closed-loop system.

The chilled mixture is then used to cool down the process equipment, which helps maintain a stable temperature and prevent overheating.

For example, in the food and beverage industry, glycol chillers are commonly used to maintain the temperature of fermenters, which are used to make beer, wine, and other alcoholic beverages. They are also used in dairy production to keep milk and cheese at the right temperature.

In the pharmaceutical industry, glycol chillers are used in the manufacturing of drugs and vaccines.

They are used to keep the temperature stable during the production process, which is crucial for ensuring the quality and efficacy of the final product.

In the plastics industry, glycol chillers are used to cool down molds used for injection molding, extrusion, and blow molding processes. These processes can generate a lot of heat, and the use of glycol ensures that the molds remain at the correct temperature, which helps maintain product quality and prevent damage to the equipment.

In the HVAC industry, glycol chillers are used to cool down the water used in air conditioning systems. This helps regulate the temperature and humidity of indoor spaces, ensuring comfort for occupants.

Overall, glycol chillers are a versatile solution for maintaining precise temperature control in various projects and industries. They offer reliability, efficiency, and ease of use, making them a popular choice for businesses that require temperature-sensitive processes.

Kaydeli is a leading manufacturer of high-quality Glycol chillers, which are widely used in various industries, including food and beverage, chemical, and pharmaceuticals.

These chillers are known for their high efficiency, reliability, and ease of use, making them a popular choice for businesses that require precise temperature control for their processes.

Glycol chillers work by circulating a mixture of water and glycol through a closed-loop system. The chilled mixture is then used to cool down the process equipment, which helps maintain a stable temperature and prevent overheating. The use of glycol also prevents freezing, making it a versatile coolant for a wide range of applications.

One of the key features of Kaydeli’s Glycol chillers is their high efficiency. These chillers use advanced compressors and heat exchangers to deliver maximum cooling performance while minimizing energy consumption.

This not only saves businesses money on their energy bills but also reduces their carbon footprint, making them a sustainable choice for environmentally conscious organizations.

Another advantage of Kaydeli’s Glycol chillers is their reliability. These chillers are built to last, with high-quality components and robust construction that can withstand even the most demanding environments. They are also designed for easy maintenance, with accessible components and user-friendly controls that make it simple to diagnose and fix any issues.

Kaydeli’s Glycol chillers are also highly customizable, with a wide range of options to suit different needs and applications. They are available in a variety of sizes and capacities, with multiple compressor configurations and control options to choose from. This allows businesses to select a chiller that is perfectly tailored to their requirements, whether they need to cool a small laboratory setup or a large-scale industrial process.

In conclusion, Kaydeli’s Glycol chillers are a reliable, efficient, and versatile solution for businesses that require precise temperature control for their processes. With their high-quality construction, user-friendly controls, and wide range of customization options, they are an excellent investment for organizations that value quality and efficiency.

If you have any questions regarding Kaydeli chillers please, feel free to contact us.