The Importance of Industrial Chillers in the Coating Industry

Introduction: The coating industry plays a vital role in various sectors, including automotive, aerospace, construction, and manufacturing. Achieving high-quality coatings requires precise control over temperature and environmental conditions throughout the coating process. In this regard, industrial chillers emerge as indispensable assets, providing efficient cooling solutions that optimize productivity, enhance quality, and ensure consistency in coating applications.

Efficient Temperature Control: Industrial chillers are paramount in the coating industry for maintaining optimal temperatures during the coating process. Many coating materials, such as paints, adhesives, and sealants, require specific temperature ranges for application and curing. Industrial chillers offer precise temperature control, ensuring that coatings are applied and cured under optimal conditions, leading to superior finish quality and durability.

Preventing Material Degradation: Temperature control is critical in preventing material degradation during coating processes. High temperatures can accelerate chemical reactions, causing premature curing or drying of coating materials, and resulting in poor adhesion, cracking, or uneven finish. Industrial chillers regulate temperatures within production facilities, preventing overheating and preserving the integrity of coating materials, thereby reducing waste and enhancing product consistency.

Enhanced Equipment Performance: Industrial chillers play a crucial role in maintaining the performance of coating equipment, such as spray booths, rollers, and curing ovens. Excessive heat generated during operation can compromise the efficiency and lifespan of equipment components. By dissipating heat effectively, chillers help prevent equipment overheating, minimize downtime, and prolong equipment service life, ensuring continuous and reliable operation in coating facilities.

Optimized Process Efficiency: The use of industrial chillers in coating operations contributes to enhanced process efficiency and productivity. By maintaining stable temperatures, chillers enable faster curing times, reduced cycle times, and increased throughput. Moreover, precise temperature control minimizes the need for rework and adjustments, streamlining production workflows and maximizing resource utilization, ultimately leading to cost savings and improved competitiveness.

Environmental and Safety Benefits: Industrial chillers offer environmental and safety benefits by mitigating the risk of hazardous conditions in coating facilities. Controlling temperatures prevents the buildup of volatile organic compounds (VOCs) and other harmful emissions associated with overheating or improper curing of coating materials. Additionally, chillers help maintain comfortable working conditions for personnel, ensuring compliance with occupational health and safety regulations.

Conclusion: Industrial chillers play a pivotal role in enhancing coating processes within the manufacturing industry. By providing efficient temperature control, preventing material degradation, optimizing equipment performance, and improving process efficiency, chillers contribute to the production of high-quality coatings with consistent performance and durability. As the coating industry continues to evolve, the importance of industrial chillers as integral components of coating operations cannot be overstated, highlighting their indispensable role in achieving superior coating outcomes and driving innovation in surface finishing technologies.

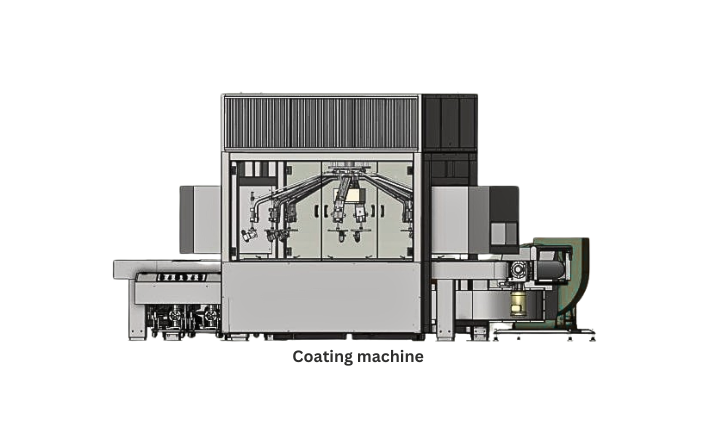

Coating/Spray machine