How Glycol Chillers Works In The Brewing Industry

A glycol chiller is an essential component in the brewing industry as it helps maintain the ideal temperature for the brewing process. The brewing process involves a complex series of chemical reactions that are temperature-dependent. As such, it is crucial to keep the temperature within a specific range to ensure that the beer quality is consistent and of high quality.

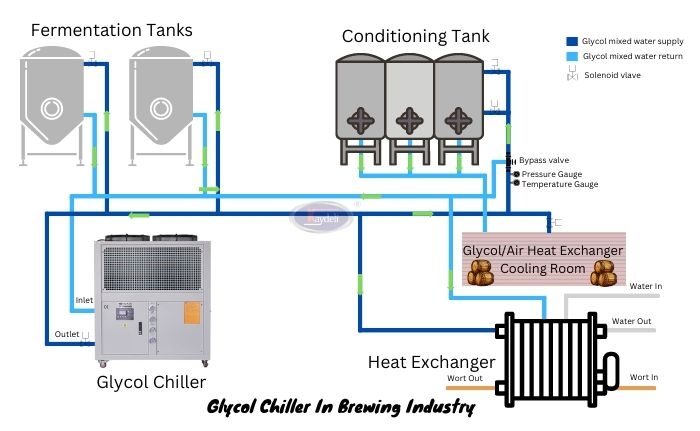

Glycol chillers are used to regulate the temperature of the glycol solution, which is then circulated through the cooling jackets of the fermenters and bright tanks. The glycol solution absorbs the heat generated during fermentation and transfers it to the chiller, where it is expelled into the atmosphere. This process prevents the beer from overheating, which can lead to undesirable flavors and aromas.

Here is how it works:

Glycol chillers work by circulating a glycol solution through a closed-loop system that includes fermentation tanks, conditioning tanks, and heat exchangers. The glycol solution absorbs the heat generated during the fermentation process and transfers it to the chiller, where it is expelled into the atmosphere.

The glycol solution is pumped through cooling jackets that surround the fermentation and conditioning tanks. As the glycol solution circulates through the jackets, it absorbs the heat generated by the yeast during fermentation. The heated glycol solution is then pumped back to the chiller, where it is cooled down before being recirculated through the cooling jackets.

Glycol chillers can also provide cooling for the storage room by circulating cool glycol solution through air handling units. This process helps maintain a consistent temperature in the storage room, preventing spoilage of the beer.

In addition to cooling the fermentation and conditioning tanks, glycol chillers can also be used in heat exchangers to chill the beer. The beer is passed through a heat exchanger that is cooled by the glycol solution. As the beer passes through the heat exchanger, it is rapidly cooled down to the desired temperature before being transferred to the conditioning tanks.

Glycol chillers are also used in other industries such as food processing, pharmaceuticals, and HVAC systems. In the food processing industry, glycol chillers are used to maintain the temperature of food products during production. For example, they are used to cool chocolate during the tempering process or to keep ice cream mixtures at a specific temperature during production.

In the pharmaceutical industry, glycol chillers are used to maintain the temperature of vaccines and other medications. Vaccines require strict temperature control during storage and transportation to ensure their efficacy. Glycol chillers are used to keep the vaccines at a specific temperature range to prevent degradation and ensure their effectiveness.

In HVAC systems, glycol chillers are used to cool water that is circulated through air handling units to regulate the temperature of a building. This process helps maintain a comfortable indoor environment for occupants.

In conclusion, glycol chillers are essential components in various industries, including the brewing industry. They help maintain the ideal temperature for different processes, ensuring consistent quality and preventing spoilage. Other industries such as food processing, pharmaceuticals, and HVAC systems also rely on glycol chillers for temperature regulation.

Why Glycol Chillers Are For High Precision Cooling

Glycol chillers are used in various projects across different industries for their ability to maintain precise temperature control. They work by circulating a mixture of water and glycol through a closed-loop system.

The chilled mixture is then used to cool down the process equipment, which helps maintain a stable temperature and prevent overheating.

For example, in the food and beverage industry, glycol chillers are commonly used to maintain the temperature of fermenters, which are used to make beer, wine, and other alcoholic beverages. They are also used in dairy production to keep milk and cheese at the right temperature.

In the pharmaceutical industry, glycol chillers are used in the manufacturing of drugs and vaccines.

They are used to keep the temperature stable during the production process, which is crucial for ensuring the quality and efficacy of the final product.

In the plastics industry, glycol chillers are used to cool down molds used for injection molding, extrusion, and blow molding processes. These processes can generate a lot of heat, and the use of glycol ensures that the molds remain at the correct temperature, which helps maintain product quality and prevent damage to the equipment.

In the HVAC industry, glycol chillers are used to cool down the water used in air conditioning systems. This helps regulate the temperature and humidity of indoor spaces, ensuring comfort for occupants.

Overall, glycol chillers are a versatile solution for maintaining precise temperature control in various projects and industries. They offer reliability, efficiency, and ease of use, making them a popular choice for businesses that require temperature-sensitive processes.

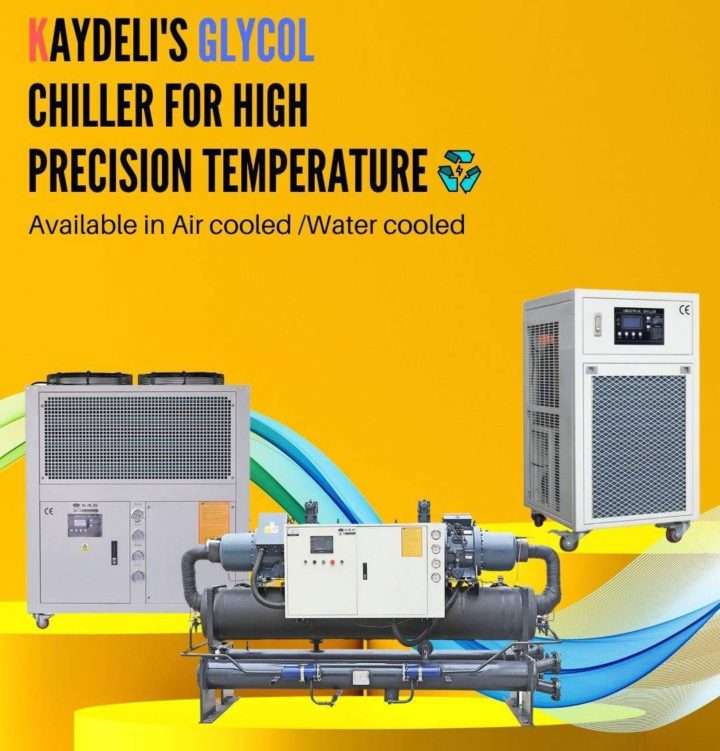

Kaydeli is a leading manufacturer of high-quality Glycol chillers, which are widely used in various industries, including food and beverage, chemical, and pharmaceuticals.

These chillers are known for their high efficiency, reliability, and ease of use, making them a popular choice for businesses that require precise temperature control for their processes.

Glycol chillers work by circulating a mixture of water and glycol through a closed-loop system. The chilled mixture is then used to cool down the process equipment, which helps maintain a stable temperature and prevent overheating. The use of glycol also prevents freezing, making it a versatile coolant for a wide range of applications.

One of the key features of Kaydeli’s Glycol chillers is their high efficiency. These chillers use advanced compressors and heat exchangers to deliver maximum cooling performance while minimizing energy consumption.

This not only saves businesses money on their energy bills but also reduces their carbon footprint, making them a sustainable choice for environmentally conscious organizations.

Another advantage of Kaydeli’s Glycol chillers is their reliability. These chillers are built to last, with high-quality components and robust construction that can withstand even the most demanding environments. They are also designed for easy maintenance, with accessible components and user-friendly controls that make it simple to diagnose and fix any issues.

Kaydeli’s Glycol chillers are also highly customizable, with a wide range of options to suit different needs and applications. They are available in a variety of sizes and capacities, with multiple compressor configurations and control options to choose from. This allows businesses to select a chiller that is perfectly tailored to their requirements, whether they need to cool a small laboratory setup or a large-scale industrial process.

In conclusion, Kaydeli’s Glycol chillers are a reliable, efficient, and versatile solution for businesses that require precise temperature control for their processes. With their high-quality construction, user-friendly controls, and wide range of customization options, they are an excellent investment for organizations that value quality and efficiency.

If you have any questions regarding Kaydeli chillers please, feel free to contact us.