A Case Study

Enhancing Dairy Production with Kaydeli Chillers.

Kaydeli chillers emerge as indispensable assets in dairy production, facilitating optimal cooling conditions, enhancing efficiency, and ensuring product quality across various production stages.

Kaydeli Solution

Customized Chiller Solutions: Kaydeli provided tailored chillers, such as the KDCS-160LLA and KDCS-180DLA, to meet the unique needs of Nutrizone Limited's milk production process.

Efficiency and Energy Savings: Kaydeli chillers prioritize energy efficiency, reducing both refrigerant loss and energy consumption, thereby decreasing operating costs for dairy producers.

Details of the project

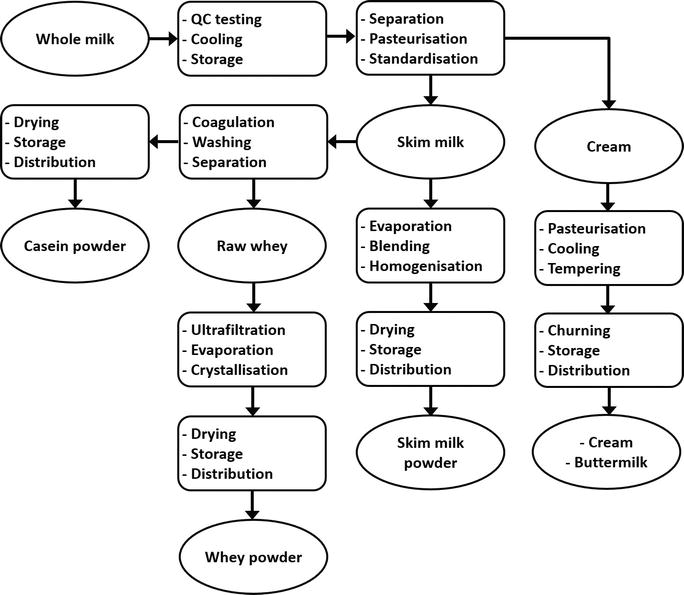

Industrial chillers serve as indispensable components in the dairy production sector, guaranteeing the quality and safety of dairy products. These chillers play a vital role in maintaining optimal cooling conditions throughout the production process, adhering to stringent temperature requirements. They facilitate the cooling of milk, cream, and other dairy ingredients, preserving freshness and averting potential spoilage. Additionally, industrial chillers contribute to the production of various dairy items such as yogurt, cheese, and ice cream, offering precise temperature control during fermentation, aging, and freezing stages. Through the adoption of dependable chillers, dairy producers uphold product integrity, prolong shelf life, and ensure compliance with regulatory standards, thereby delivering premium-quality dairy products to consumers worldwide.

This article sheds light on the dairy industry's reliance on chillers and their application within yogurt and other dairy production processes, particularly focusing on the use of Kaydeli chillers.

New Zealand Nutrizone Limited, a prominent player in the New Zealand food industry specializing in milk product manufacturing, sought solutions from Kaydeli's Foreign Trade Department due to the latter's reputation for supplying industrial chillers for various refrigeration projects in the dairy and beverage sectors. Collaboration ensued, with specific parameter requirements laid out to meet production demands while ensuring safety, reliability, and cost-effectiveness.

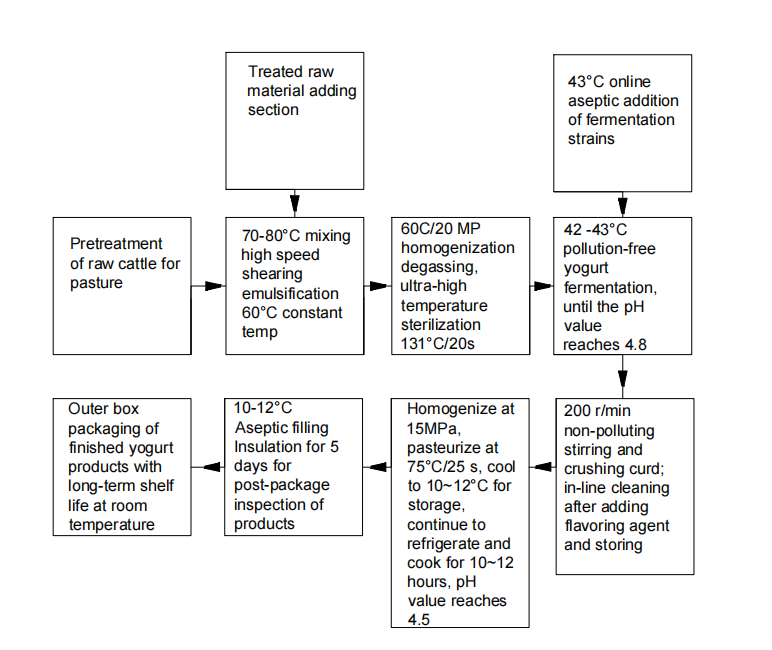

After an in-depth analysis of the client's milk production processes, our engineering team recommended two air-cooled twin-screw chillers, namely KDCS-160LLA and KDCS-180DLA. These chillers were tailored to suit the requirements of the production equipment, which included raw milk storage and pretreatment machinery, mixing equipment, ultra-high temperature sterilization units, yogurt fermentation tanks, pasteurization equipment, aseptic filling systems, and CIP cleaning apparatus.

The chillers played a pivotal role in milk production, serving as the cold source for low-temperature cooling systems to regulate process temperatures and control bacterial growth. The rapid cooling capability ensured an optimal temperature environment for milk production, thereby preserving quality.

Key features of Kaydeli chillers utilized in the milk cooling system include:

- Low refrigerant losses: Dedicated efforts to minimize environmental impact and enhance equipment efficiency.

- Energy efficiency: Reduced energy consumption leads to lower operating costs and increased production capacity.

- Maintenance ease: Incorporation of easy-to-clean heat exchangers, reducing maintenance time and costs for dairy enterprises.

The KDCS-160LLA and KDCS-180DLA chillers offer adjustable temperature ranges of (7~30°C and 0) respectively, catering to diverse production needs. They incorporate air-cooled condenser units, refrigeration compressors, evaporators, and electric control systems, configured based on environmental factors to achieve milk cooling requirements.

Dairy farms can achieve up to 30% savings on milk chilling costs using plate heat exchangers with Kaydeli chillers. Moreover, the adoption of high-efficiency screw compressors, such as those from the Hanbell brand, ensures enhanced refrigeration efficiency and prolonged compressor lifespan.

Following installation and commissioning, the chillers successfully fulfilled milk production cooling requirements, demonstrating their versatility in both milk collection and pasteurization processes.

In conclusion, Kaydeli chillers emerge as indispensable assets in dairy production, facilitating optimal cooling conditions, enhancing efficiency, and ensuring product quality across various production stages.